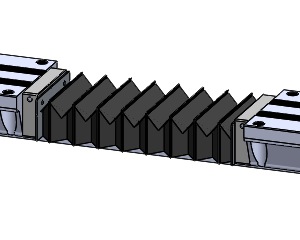

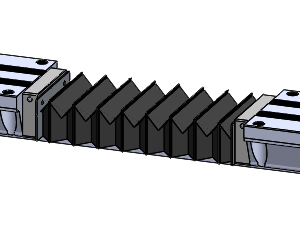

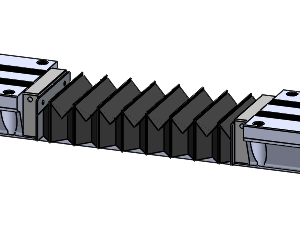

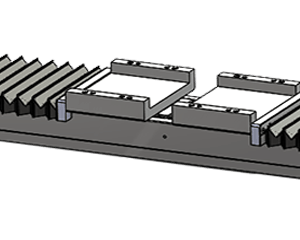

Medical Bellows

Precision and quality are two important requisites of the medical instrumentation industry. At Nabell USA Corp, we meet these requirements by providing precision designed custom-made medical bellows of the highest quality. Made from FDA-approved grades of plastic and synthetic materials, our bellows are utilized by both— invasive and non-invasive equipment manufacturers. They provide perfect sealing to other components or assemblies of the equipment where they are used. Our vast experience and commitment to quality help us assure our medical bellows are built to the performance requirements of medical industries around the world.

Specifications of Medical Bellows Provided by Nabell USA

Being one of the most well-known manufacturers of custom-made medical bellows, we have designed and delivered medical bellows in various specifications. The following capabilities have immensely helped us fulfill complex requirements with ease:

- Applied Processes: We use wire inserts that define the shape of bellows, and offer excellent impact resistance. The bellows are manufactured through various techniques such as perforation folding and thermal welding.

- Base Materials: We manufacture bellows from a vast range of base materials such as PVC-coated polyester, PVC-coated Nylon, polyurethane-coated nylon, TPU, Viton, EPDM PU-coated polyester, urethane-coated Nomex, Hypalon, Neoprene, Chloroprene, Kevlar, Aramid fibers and many more.

- Shapes: The bellows can be designed in rectangular, round, and many custom shapes.

- Material Thickness: The bellows are provided in material thicknesses 0.2mm–0.3mm.

- Colors: We manufacture bellows using an array of stocked colors and can color match to your choice.

- Packaging: The bellows can be delivered in packaging specified by customers.

- Delivery Times: We can provide prototypes in the shortest lead-time of four to five weeks.

- File Types Accepted: We accept design files in different formats such as DWG, DXF, STEP, and Native SolidWORKS

- Tooling Costs: In most cases, we don’t charge any tooling costs to our clients.

Applications of Medical Bellows

Over the years, we have designed and delivered several pharmaceutical processing bellows as well as other bellows for the following medical applications:

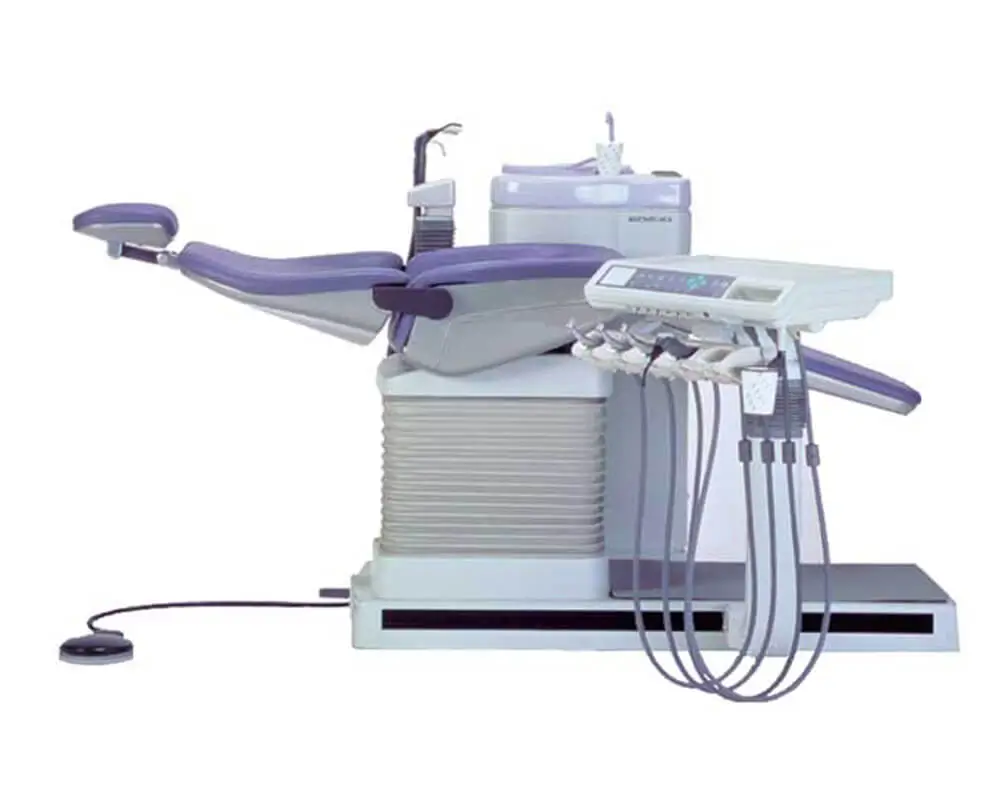

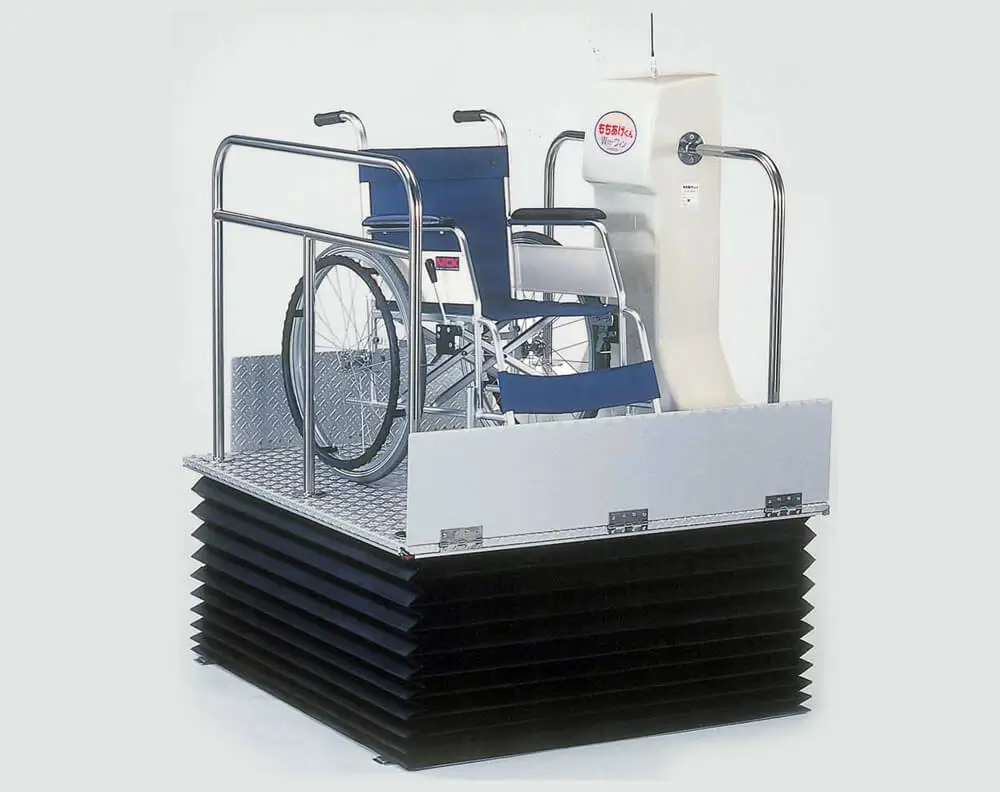

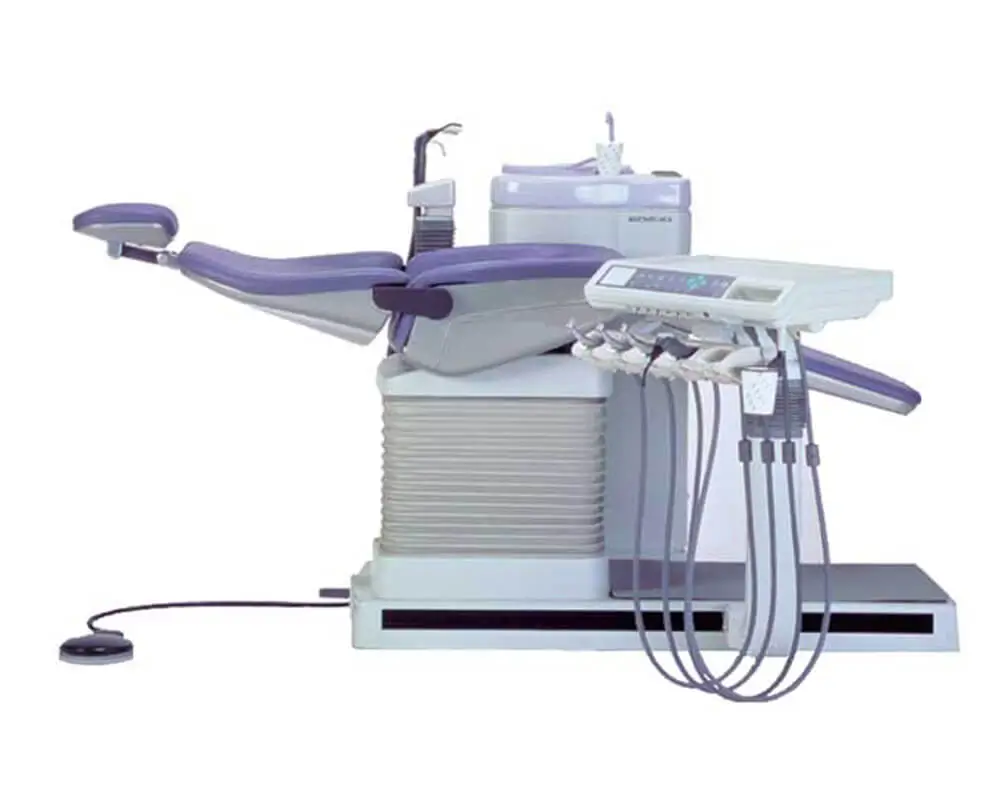

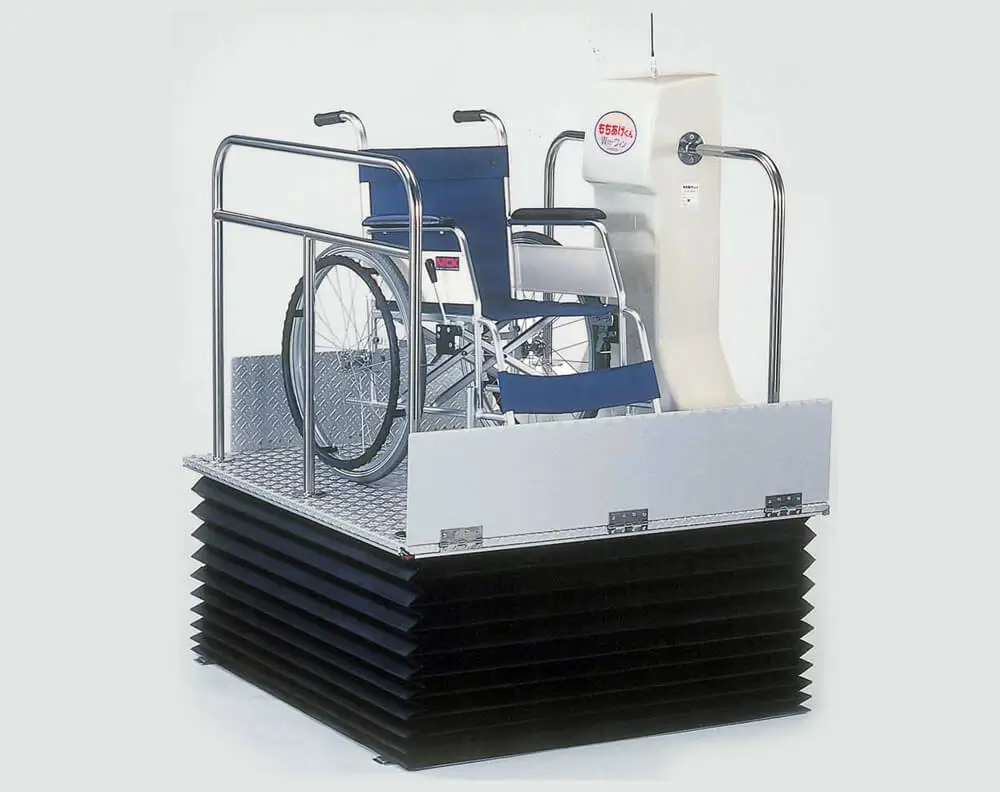

- Surgical Tables

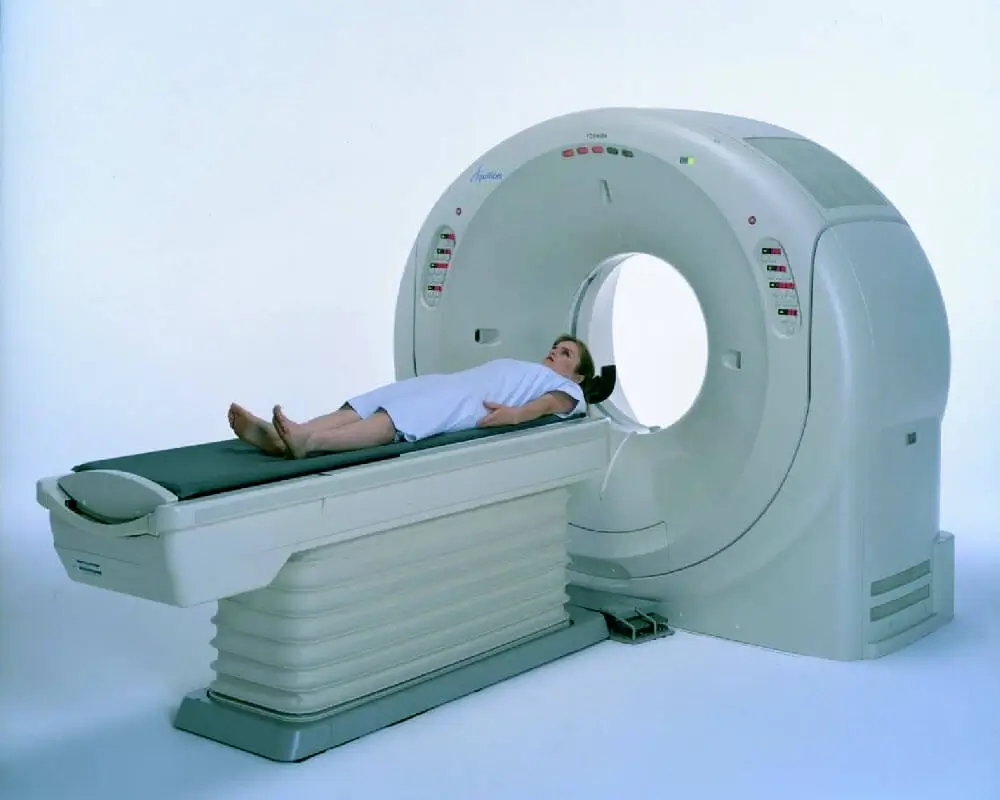

- CAT Scan machines

- PET machines

- MRI machines and tables

- Scanning imaging machines

- Cable and Harness wraps

- Blood pumps and centrifuge

- Vacuum pumps and Respirators

Certifications & Standards

Our advanced manufacturing facility and continuous investment in technologies have helped us emerge as one of the trusted custom medical bellows manufacturers in the US. Our custom medical bellows assure high-quality performance for various challenging applications. The state-of-the-art manufacturing processes are conducted under the highest standards. From design to manufacturing, the entire process is monitored by our seasoned experts. The following certificates and compliances show our commitment to quality in everything we do.

Certifications

- ISO 9001:2015

Compliances

- UL94-VTM0 test standard for wire insert bellows

Nabell USA Corp, being renowned medical bellow suppliers, are committed to providing innovative medical bellows for surgical devices and equipment, as well as medical devices. All our medical bellows are designed for long-term use and assure reliability owing to their zero-leakage and maintenance free operations. Our team comprises design engineers with a vast industry experience, who help medical innovators design innovative solutions that help save lives of millions of people.

Additional Information :

|

Product Specification |

|

|---|---|

| Capabilities Applied/Processes | Wire Insert, Perforation Fold, Thermal Welded |

| Material Thickness | 0.2mm – 3.0mm |

| Base Material Selection | PVC coated Polyester, Polyurethane coated Nylon, Polyurethane coated Polyester, Polyurethane coated Nomex |

| Color | An array of standard colors or custom color matching is available |

| Packaging | To customers specifications |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally None |

| Industries Served Include |

|

Medical Bellows Quote Request Form

Medical Bellows Quote Request Form