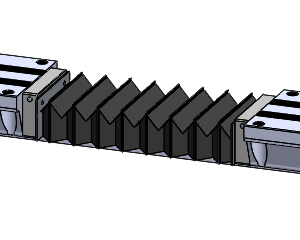

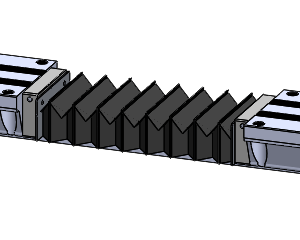

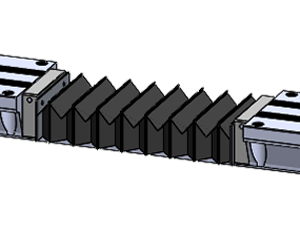

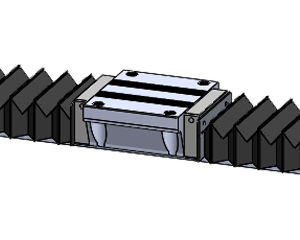

CMM Bellows

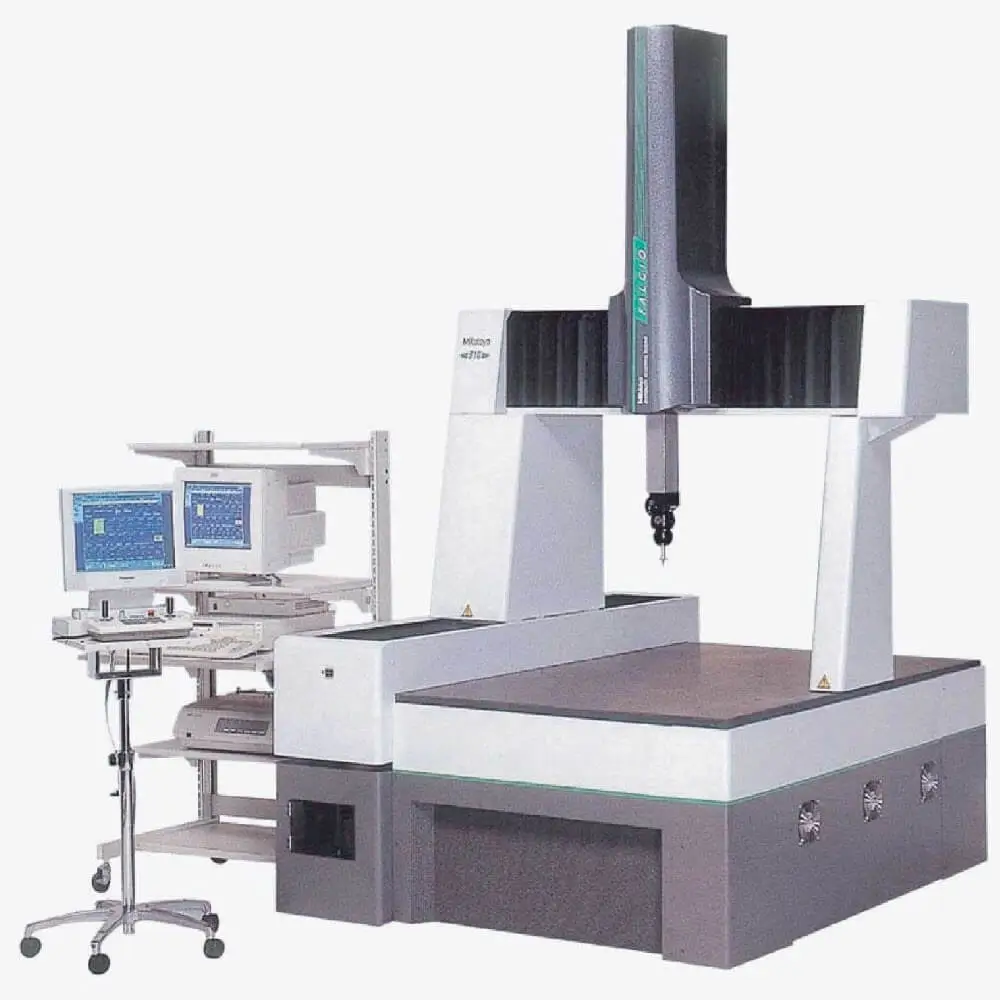

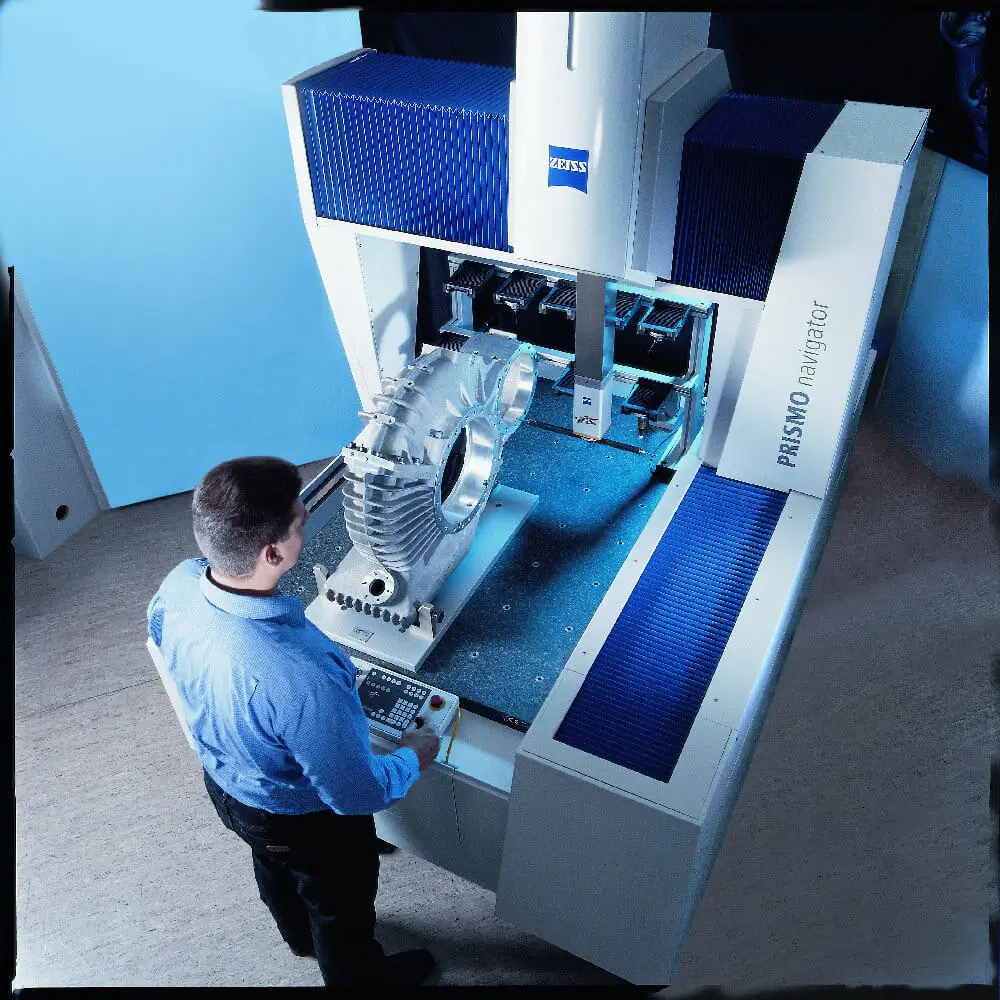

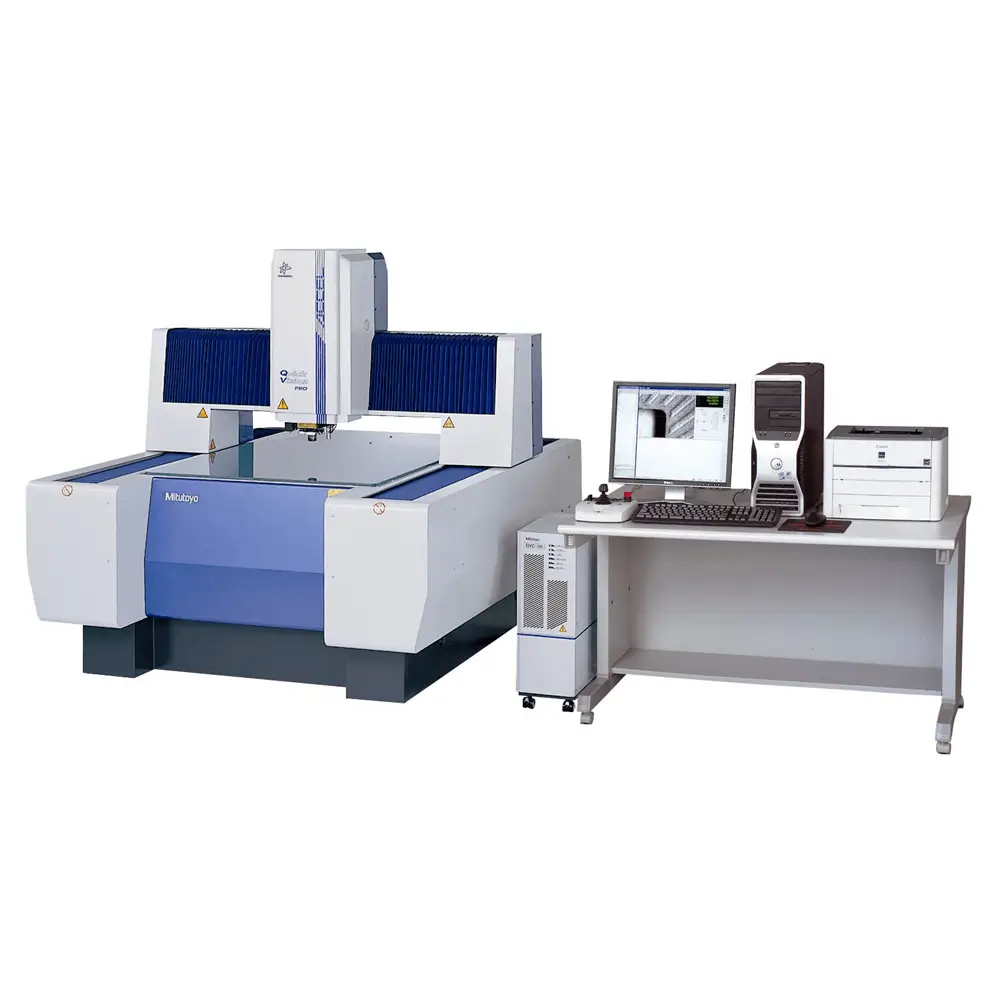

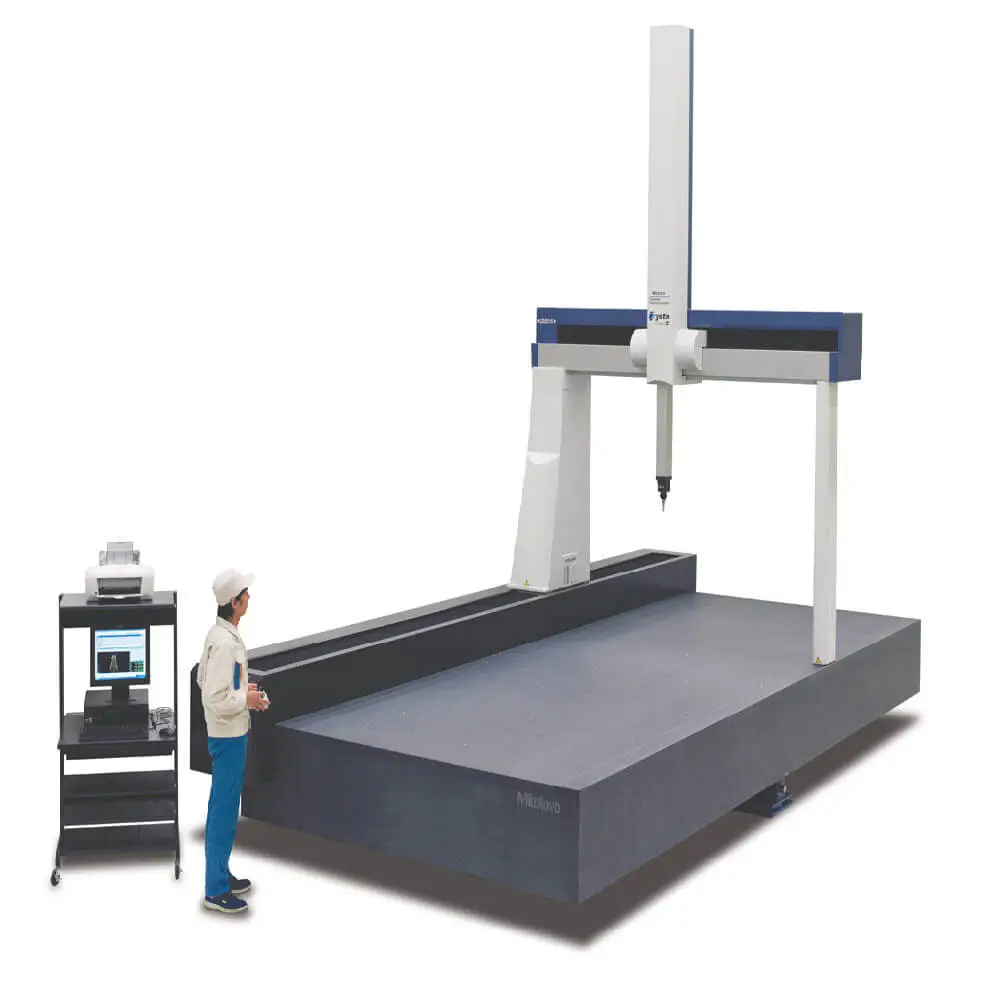

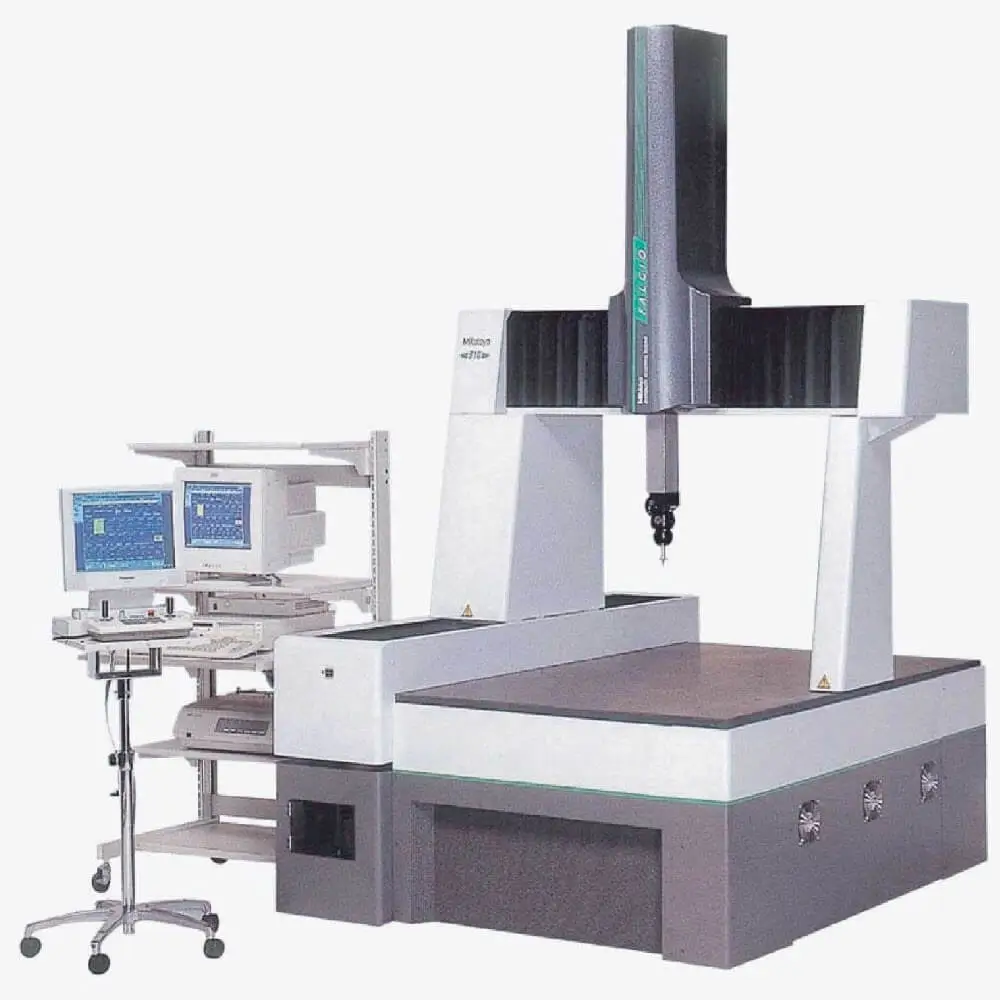

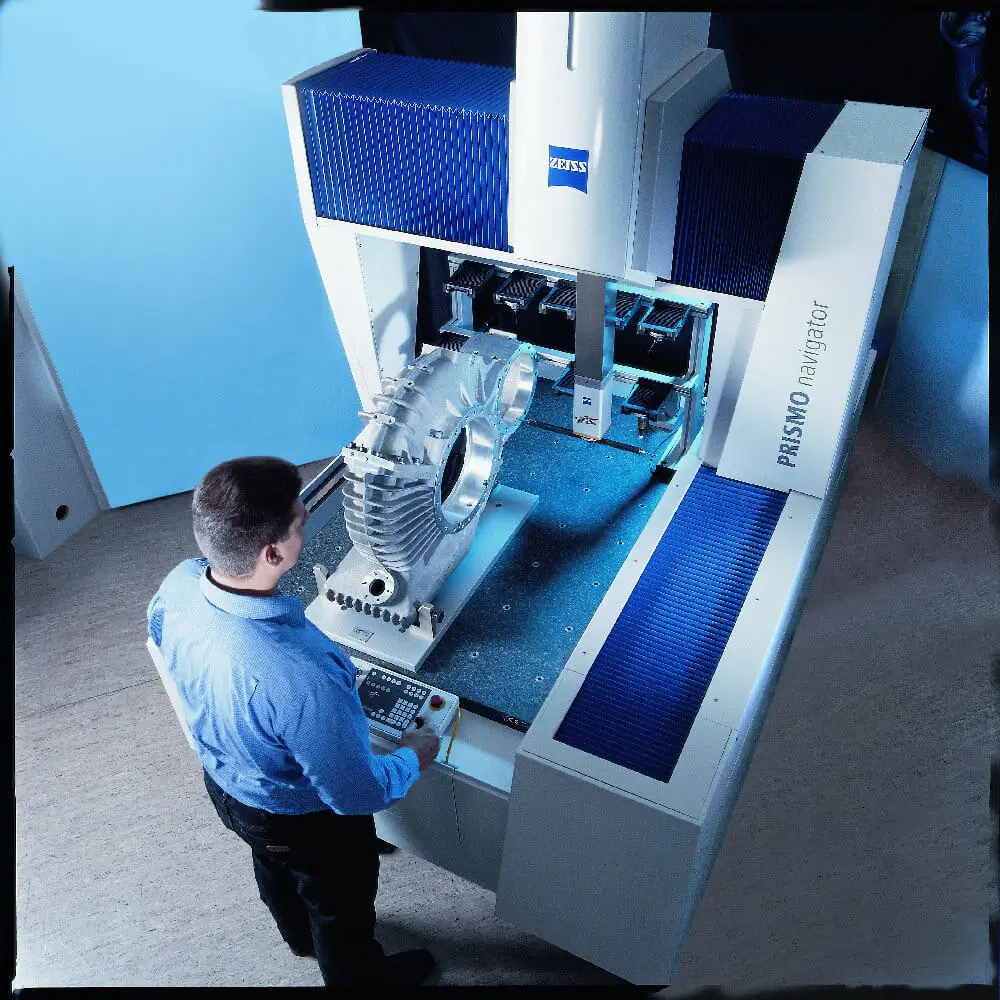

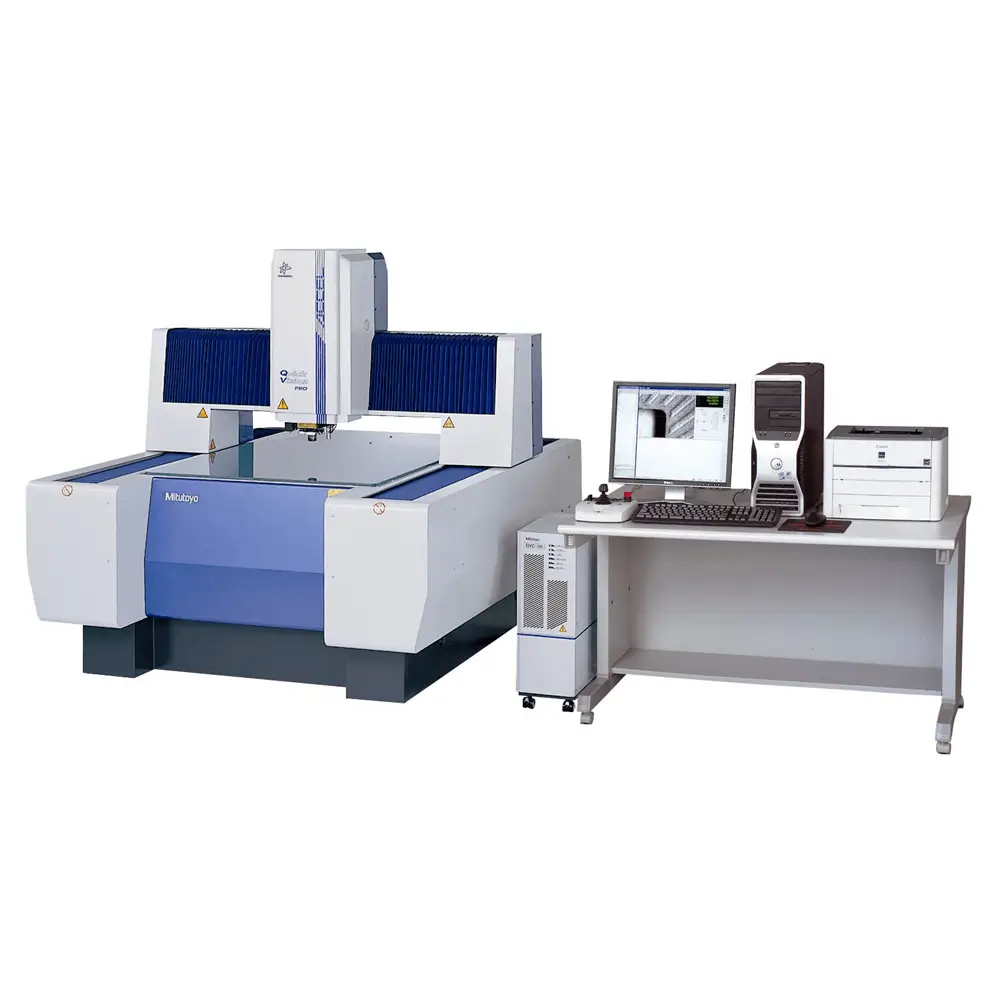

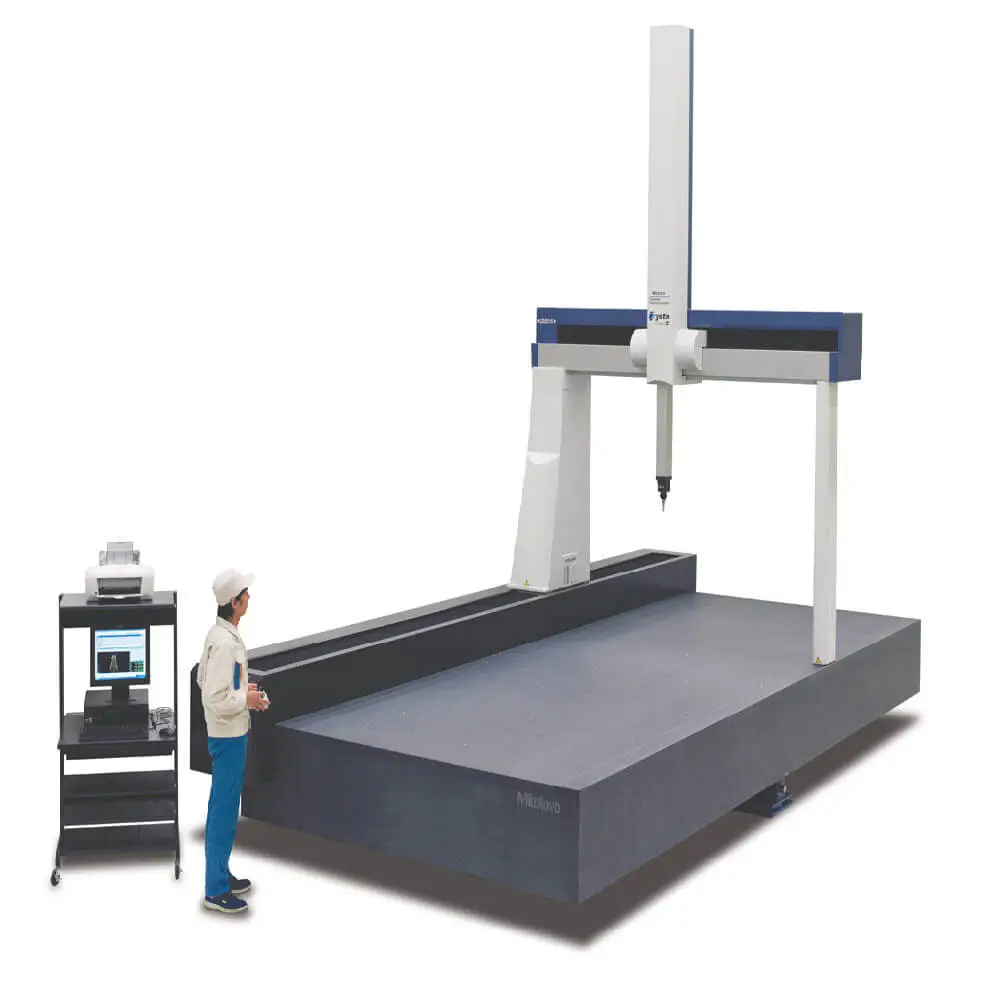

Because precision instruments have unique requirements, Nabell USA Corporation has developed a thin, Polyurethane-coated, Polyester fabric to manufacture CMM bellows. Our special lightweight material is flexible to enable easy thermal expansion and contraction as well as provide general dust protection with minimal drag. Suitable for even the most sensitive, high-precision equipment, our CMM bellows can be delivered with shorter lead-time requirements. To learn how to get started, please contact Nabell USA today.

Because precision instruments have unique requirements, Nabell USA Corporation has developed a thin, Polyurethane-coated, Polyester fabric to manufacture CMM bellows. Our special lightweight material is flexible to enable easy thermal expansion and contraction as well as provide general dust protection with minimal drag. Suitable for even the most sensitive, high-precision equipment, our CMM bellows can be delivered with shorter lead-time requirements. To learn how to get started, please contact Nabell USA today.

Additional Information:

1. Know About CMM Bellows

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Thermal Welding, |

| Material Thickness | 0.16 mm |

| Base Material Selection | Polyurethane coated Polyester |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Industry for Use | High precision equipment |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

CMM Bellows Quote Request Form

CMM Bellows Quote Request Form