Metal bellows are flexible components vital to modern engineering equipment. Constructed from materials like stainless steel, inconel, and other alloys, they are chosen for their durability, corrosion resistance, and strength under pressure. These unique materials enable metal bellows to expand, contract, and absorb movement, making them ideal for applications where flexibility and vibration absorption are important. Also, metal bellows help create a seal that prevent a machine from being affected by external temperature, pressure, and other elements. Metal bellows are widely used in aerospace, medical, automotive, and industrial settings to handle variable pressure, movement, and temperature. This post explores how metal bellows work, their advantages, diverse applications, design challenges, and best practices for maintenance and cleaning to ensure optimal performance and longevity.

How Metal Bellows Work?

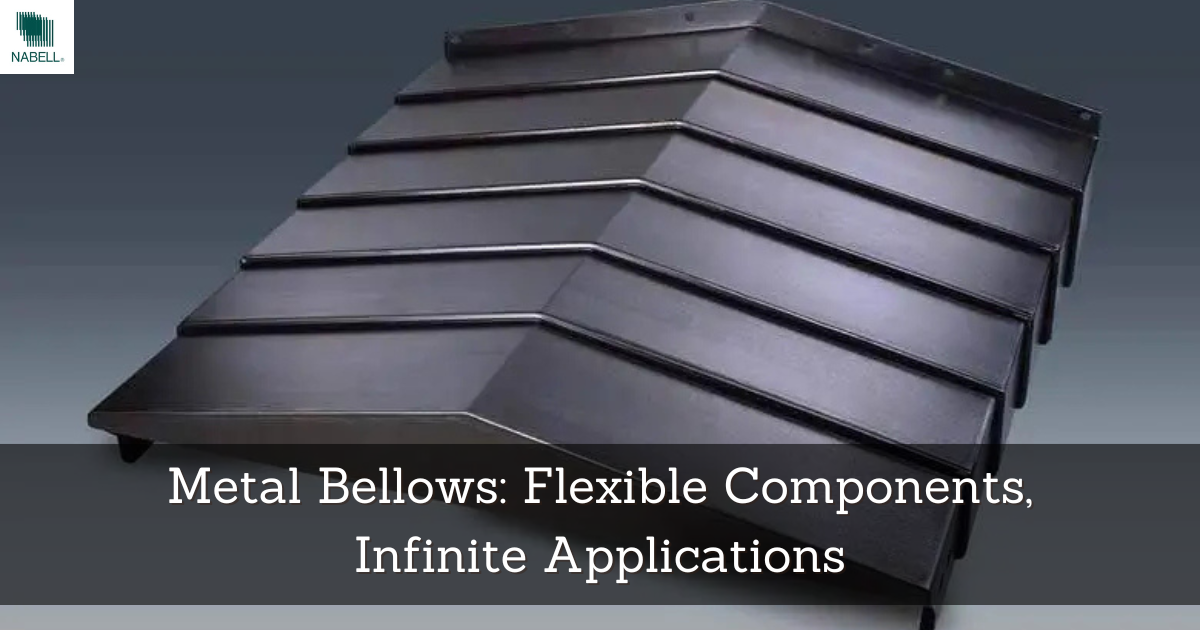

Metal bellows operate as an essential shield in various mechanical systems by managing movement and accommodating changes in volume and pressure. They are manufactured through a precision process that involves shaping thin metal layers into a series of rounded folds or corrugations. This design enables the bellows to flexibly expand, contract, or bend in response to applied pressure or external forces. When fluid or gas pressure is introduced, the bellows adjust by either extending or compressing, depending on the direction of the force, enabling the system to absorb shifts in temperature, pressure, and movement without damaging other components. They also isolate vibrations and prevent leakage, making them valuable in sensitive applications such as aerospace, industrial, and medical devices where sealing and precision are critical. The durable metals used in these bellows, such as stainless steel or nickel alloys, ensure resilience in extreme temperatures and high-pressure environments, while maintaining flexibility and elasticity over prolonged usage. This capability to withstand significant variations in force, pressure, and temperature makes metal bellows indispensable in ensuring system stability and protecting against wear, failure, or inefficiency in demanding applications.

Advantages of Using Metal Bellows in Industrial Settings

Metal bellows are integral components in various industrial applications, providing exceptional functionality under challenging conditions. Their unique design and material composition offer multiple benefits, making them invaluable in settings where precision and reliability are paramount.

- High Reliability and Durability: Metal bellows are engineered to maintain performance even in extreme environments. Their robust construction ensures long-term reliability, reducing the need for frequent maintenance or replacements and enhancing operational efficiency.

- Precision in Movement Control: These components allow for highly accurate movement control, essential in fields like aerospace, robotics, and other precision-driven engineering applications. This precision helps in executing delicate tasks where even slight inaccuracies can lead to major issues.

- Resistance to Environmental Factors: Metal bellows are built to withstand high temperatures, corrosive substances, and fluctuating pressures, making them ideal for harsh industrial settings. This resilience extends their lifespan and ensures consistent performance regardless of environmental challenges.

- Vibration Damping and Noise Reduction: By minimizing vibrations and noise, metal bellows improve both safety and performance in industrial equipment. This feature is particularly beneficial for equipment longevity and worker safety, reducing wear and tear on machinery.

Application of Metal Bellows Used in Modern Engineering

Metal bellows’ design and material resilience enable them to withstand extreme temperatures, corrosive substances, and heavy mechanical stress, making them essential across industries. Below are some key applications of metal bellows.

- Refinery and Petrochemical: Metal bellows manage temperature fluctuations and contain corrosive gases and liquids, ensuring the safety and efficiency of operations in compliance with industry standards for handling cutting oils and extreme temperatures.

- Steel, Wood, Aluminum, and Plastics: They protect against dust, chips, and hot splatter in metal and woodworking environments. Metal bellows prevent contamination from grinding swarf and high temperatures, adhering to safety and durability requirements.

- Water and Irrigation: Used in pump systems, metal bellows provide flexible sealing that withstands moisture and minimizes wear from constant water exposure, ensuring longevity and meeting water industry standards.

- Pulp and Paper: Metal bellows handle the abrasive pulp and moisture-heavy environment, reducing maintenance in papermaking machines and meeting operational requirements for long-lasting performance.

- Food and Beverages: Metal bellows resist cleaning chemicals, oils, and coolants in food processing to ensure contamination-free production.

- Pharmaceutical and Medical: They offer contamination-free sealing in medical devices, handling precision fluids without exposure to outside contaminants, thus meeting stringent medical standards.

- Energy: From oil and gas to renewable energy, metal bellows withstand extreme temperatures and corrosive conditions, adhering to safety standards in high-stress environments like refineries and power plants.

- Automobile and Construction Machinery: Metal bellows prevent contaminants like dust, debris, and moisture from entering sensitive vehicle and machinery parts, ensuring durability and safety in rugged operational conditions.

- Aerospace and Marine: Used for vibration absorption and sealing, metal bellows protect aerospace and marine equipment from salt spray, temperature shifts, and pressure changes.

- Housing Equipment: It enables durable, leak-proof sealing in HVAC systems, ensuring safe operation and energy efficiency.

- Salt and Mineral Mining: Resistant to corrosive salts and abrasive particles, metal bellows protect mining equipment, adhering to environmental durability standards.

- Semiconductor and IT: They provide precise, contamination-free movement in sensitive semiconductor manufacturing, safeguarding delicate electronics and adhering to high-purity standards.

What Are the Design Challenges and Solutions in Metal Bellows?

Metal bellows are essential for various industrial applications, but designing them comes with challenges due to the need for precision and durability.

- Material Selection: The choice of material impacts the bellows’ performance with regards to resistance to fatigue, corrosion, and temperature changes. Selecting the right alloy ensures longevity in harsh conditions, particularly in environments involving high pressure or chemical exposure.

- Finite Element Analysis (FEA) and Modeling: FEA allows engineers to predict and optimize bellows performance, simulating stresses and displacements in various conditions. This predictive modeling is essential for creating designs that meet specific application demands.

- Manufacturing Challenges: Precision is critical, especially for custom or tight-tolerance applications. Meeting stringent manufacturing specifications requires advanced machining and quality control to ensure every component performs flawlessly.

Best Practices for Maintenance and Cleaning of Metal Bellows

Maintaining and cleaning metal bellows is essential to ensure their longevity and optimal performance. Here are some best practices recommended by leading metal bellows manufacturers.

- Regular Inspection: Periodically inspect metal bellows for any signs of wear, corrosion, or damage to address issues before they escalate.

- Use Appropriate Cleaning Agents: Always use cleaning agents compatible with the bellows’ material to prevent chemical damage.

- Avoid Excessive Force: Handle bellows gently, avoiding excessive force that can deform or damage the structure.

- Lubrication: Apply suitable lubricant to reduce friction and improve flexibility as recommended by metal bellows manufacturers.

- Environmental Control: Store and operate metal bellows in environments free of contaminants to minimize corrosion and deterioration risks.

Are you looking for metal bellows suppliers in the USA? Nabell USA Inc. has got you covered. We offer long-lasting, durable, and high-performance metal bellows designed to meet the critical demands of modern engineering applications. From precision to resilience, our bellows deliver unmatched quality and reliability. If you have any questions or specific requirements, contact us today to discuss how we can support your projects.