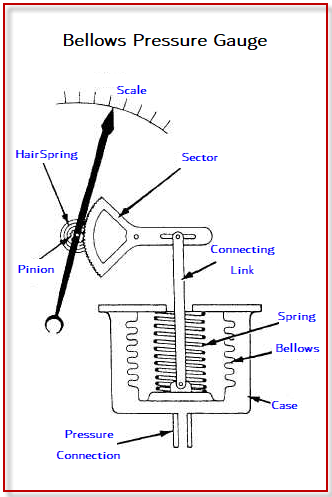

Bellows are covers usually made of rubber or metal to protect industrial machines and equipment from external damage, spillage, and so on. They increase the impact strength of the machines and also their operational life. So, what is a bellows pressure gauge? It is a unit which expands or contracts based on the changes in pressure. They are used to measure absolute as well as differential pressure. Most bellows gauges have a spring or a certain amount of elasticity, and usually the pressure is applied on it from the outer side of the bellows. Are you intrigued to know how these bellows pressure gauges work or perform? Read this post to know answers.

Working and Other Details of Bellows Pressure Gauges Explained

These bellows are seamless collapsible convoluted cylindrical units with multiple folds formed out of a thin walled tube. The diameter of this tube varies depending upon the application. When pressure is applied to the inner or outer end of these bellows, which depends upon the application, the bellows expand or contract. There is one mobile end of these bellows connected to a linkage assembly. The pressure is applied on the closed end which is the mobile end. The open end does not move. Once both bellows and the assembly move, electrical signals are produced to indicate pressure changes. At times, there are other mechanisms for pressure change output. The bellows pressure gauges are more suited for low or medium pressure applications, rather than high pressure.

The diameter of the tube is crucial when selecting pressure bellows gauges. Tubes with large diameters are suitable for low pressures. Accurate pressure measurement depends largely on the spring gradient, and to some extent on the materials used in making the gauge.

Bellows Pressure Gauges to Measure Differential Pressure Changes

Differential pressure measurement implies comparison with the existing pressure and then indicating the changes. Here, the device design is a bit different. Imagine there are two bellows, say A and B. Pressure is applied on the inner portion of sealed bellows A, while another pressure is applied on the inner portion of sealed bellows B. These bellows have spring loads and they oppose each other. Depending on the force, both the springs show deflection, and this is indicated by a pointer on a scale because of the resultant force.

Bellows Pressure Gauges to Measure Absolute Pressure Changes

When we say absolute pressure, the value or range is fixed. There are no other values to compare. Also, this pressure is not influenced by external or atmospheric changes. When pressure is applied on one end, there is a resultant deflection in the spring load. This deflection indicates the absolute pressure. However, here also, there are two bellows, but pressure is applied on only one bellows. The other one serves as a reference point with complete vacuum inside.

Benefits of Using Bellows Pressure Gauges

There are many benefits of using these gauges, especially if you deal in low to medium pressure applications. Here are some of them:

- These gauges are simple and easy to use.

- They are cost effective and low on maintenance.

- They can withstand a huge amount of force.

- You can measure absolute as well as differential pressures.

If you looking for good quality bellows for your machines or equipment with low to medium pressure application, ensure you source them from a reliable player who can customize the same to suit your requirements. Nabell USA Corp is a well-known player in a variety of bellows and way covers various applications.