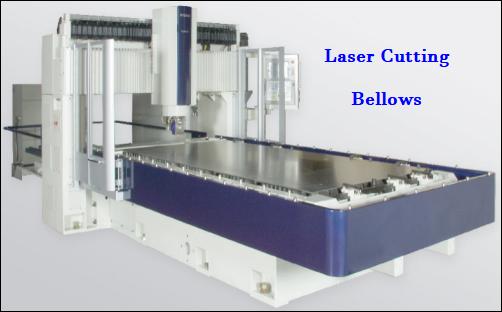

Bellows are installed in industrial setups for various reasons. They can act as friction-resisting elements, aligning elements, and more. However, in laser cutting machines they are used as protective elements. The bellows play important roles in the operation of laser cutting setups. When telescopic covers cannot be used in the laser cutting machines, perforated fold or combination fold bellows are utilized. However, it is important to use high-quality and precisely manufactured laser cutting bellows as the process of laser cutting can be quite complex. Nabell manufactures special types of laser cutting bellows that assure efficient performance in laser cutting machines. This post discusses the significance and applications of laser cutting bellows in laser cutting setups.

Introduction to Nabell’s Laser Cutting Bellows

Laser cutting bellows are the bellows designed to protect the laser (light beam) from external contaminants like dust particles. Laser beams of the laser cutting machine are extremely sensitive, thus should be protected from any other interruption.

Nabell manufactures special quality laser cutting bellows to protect the rails and gantries of these laser cutting machines. These bellows are made from materials that do not impact the optical activity of laser cutting machines. These bellows are also used to maintain the alignment of the optical emitter for precision beam positioning. Since the laser cutting machines are exposed to pressure variations, mechanical loads, compressive stresses, etc., the bellows by Nabell are designed to sustain all such conditions.

One of the specialties of laser cutting bellows is their patented solution with electrical and electronic sensors, along with aluminum reflectors that are placed inside the bellows. These ensure the safety of operators by deflecting or even powering down the lasers beam if in case the laser beam pierces through the bellows.

Let us discuss the beneficial features of Nabell’s laser cutting bellows.

Features of Nabell’s Laser Cutting Bellows

The following beneficial features of Nabell’s laser cutting bellows make them one of the best products in the industry.

- Material: These laser cutting bellows are made from one or more of the following materials and are continually updated for REACH and RoHS compliances.

- Aluminized Kevlar

- Silicone Fiberglass Cloth

- Polyurethane-Coated Polyester

- Preoxydized Kevlar

- PVC-Coated Polyester

- Polyurethane-Coated Nomex

Notes:

- All these materials are suitable for laser cutting bellows and do not impact the optical activity in any manner.

- These materials are heat resistant, flame resistant, and durable, therefore, are highly suitable for laser cutting bellows.

- Manufacturing Processes: These bellows are manufactured using different manufacturing processes. The manufacturing techniques include thermal welding, perforated folding, combination folding, and sewing.

- Thickness: Laser cutting bellows are designed and manufactured for 0.2mm to 1.17mm wall thickness.

- Shapes: These bellows are designed in square or polygonal shapes, however, they can be made in different shapes.

- Quality Certifications: Laser cutting bellows are designed and manufactured to qualify ISO 9001:2015. Also, the wire insert bellows are tested in compliance with the UL94-VTM0 standard.

The company accepts the bellow designs in formats like DWG, DXF, STEP, and native SOLIDWORKS. You can get in touch with the team at Nabell today to discuss your bellow design requirements.