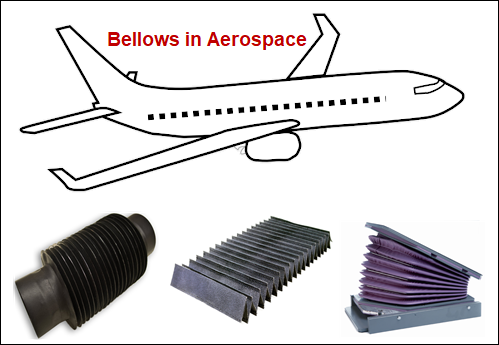

The applications in the aerospace industry are developed to withstand challenges induced by conditions such as sudden temperature rise, pressure fluctuations, chemical exposure, etc. These conditions are known to induce failure in most standard industrial equipment. While in many industries, these equipment failures may mean downtimes resulting in a waste of efforts and money, in the aerospace industry, equipment failures can impact lives. To avoid these failures, several small devices are used along with the equipment that can withstand the sudden impact of temperatures. Bellows or the expansion joints are the most prominent among them. They play an important role in the error-free, safe operation of various aerospace equipment and components. This post discusses the significance of bellows in the aerospace industry and the scope of applications for the same.

The bellows are used in various capacities for different aerospace applications. The following pointers will help you understand it better.

- Bellows can be used to align equipment and components in the aerospace industry. The aerospace equipment features multiple actuators and other mechanically moving components. The alignment of such components can be maintained during the operations using a bellows. Generally, rubber like bellows are used to restrict unwanted movement or alignment of the actuators, and other linear motion components. In a way, these bellows help ensure that the actuators perform linear motion and that no radial, rotary or angular movement takes place.

- The bellows can act as pressure sensing and sustaining equipment in aerospace applications. They can be used in the pressure gauges to check the sudden pressure rise or drop. Bellows can help prevent the equipment from abrupt failure due to high or low pressure. In certain cases, the bellows are mounted on the joints of fluid transmission lines at the bends and elbows to sustain pressure variations.

- Although featuring rugged designs, the aerospace equipment may fail when exposed to challenges such as friction between the moving components, heat generation in engine operations, exposure to environmental high temperature, etc. The bellows undergo contraction and expansion which leads to uniform heat distribution and dissipation. Therefore, thermal management in the aerospace application is performed by the bellows, to some extent.

- Leak-proofing is essential in aerospace applications. Bellows can be used for leak-proofing of lubricated components in aerospace equipment. They prevent the leakage of lubricants from the joints of aerospace equipment and help by reducing friction and enhancing the performance of the equipment.

A Few More Important Applications of Bellows in the Aerospace Industry

The bellows are used in the following aerospace industry applications.

- Speed Detection: Bellows are used in the speed detection systems of aerospace equipment. The pressure fluctuations take place in several parts of aerospace equipment due to the speed variation. The bellows help sense the minute changes in the pressure in these speed detection equipment.

- Communication Devices: The communication devices used in the aerospace industry are exposed to high-frequency signals. The bellows help minimize the impact of such high frequencies, vibrations, and dB losses on the communication equipment.

- Electronics: Bellows can help assure mechanical redundancy to the sensitive electronic equipment in the aerospace industry.

- Mechanical Actuation: Aerospace equipment possess several mechanical actuators. Although most actuation systems are electronically supported, the actual functioning mechanism is based on mechanical linkages. Bellows can be used to prevent contaminants, pressure build-up, temperature rise, misalignment, etc in these mechanical linkages.

As the functional capabilities of bellows in the aerospace industry are extremely well established, the efficiency of operation depends on the quality of the bellows. That is why it is essential to source the bellows for aerospace applications from reliable manufacturers like Nabell. The company offers high-quality, custom manufactured bellows for multiple industrial purposes as well as qualified engineers ready to discuss your needs.