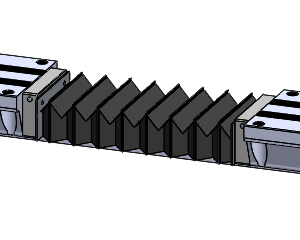

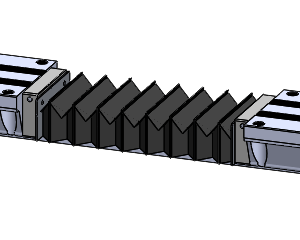

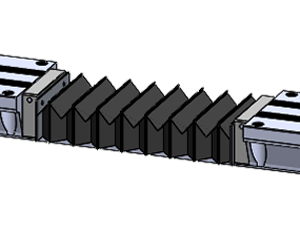

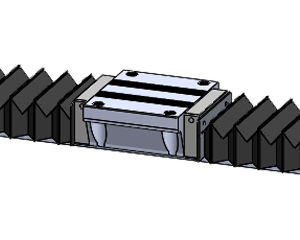

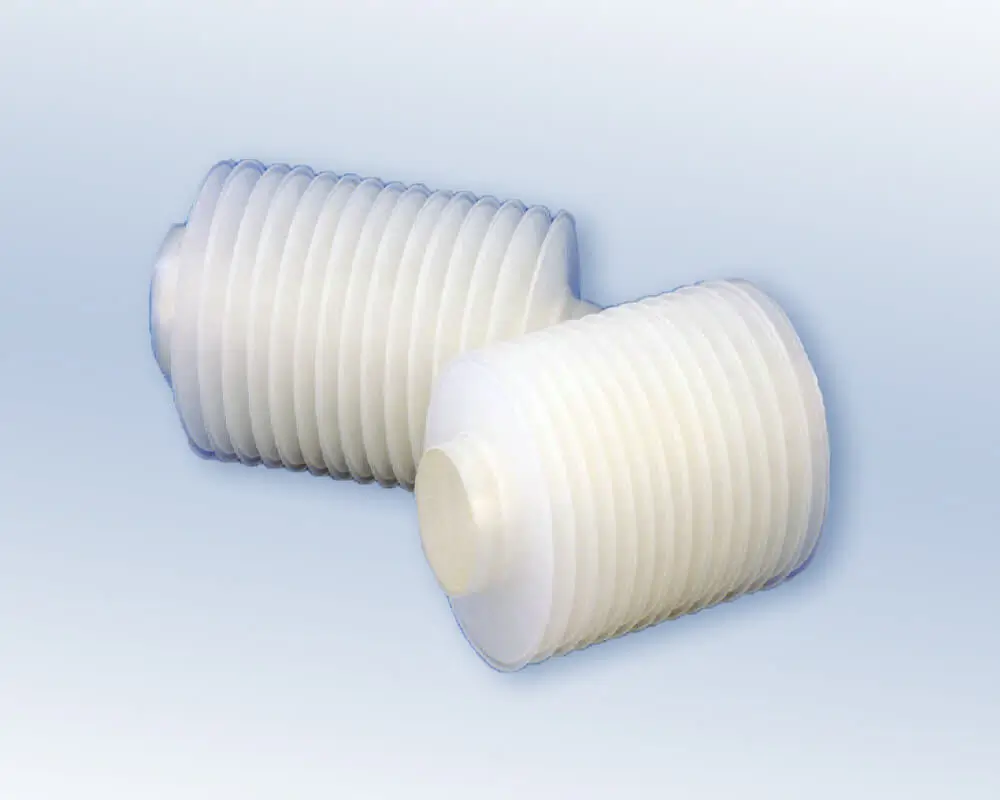

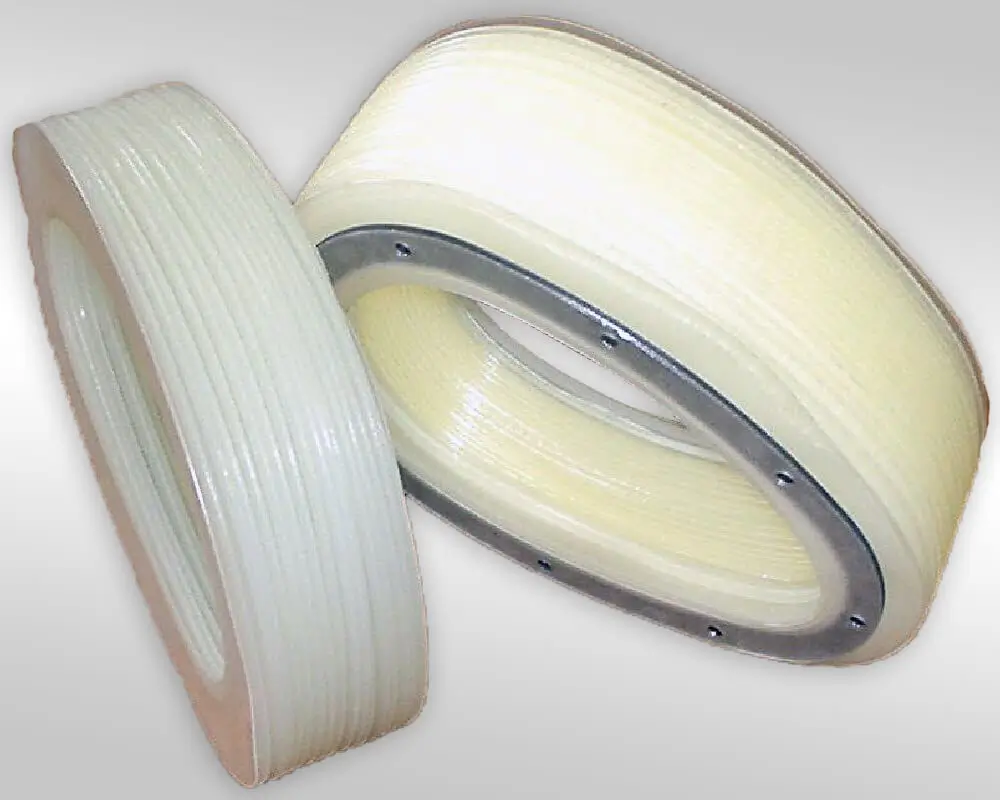

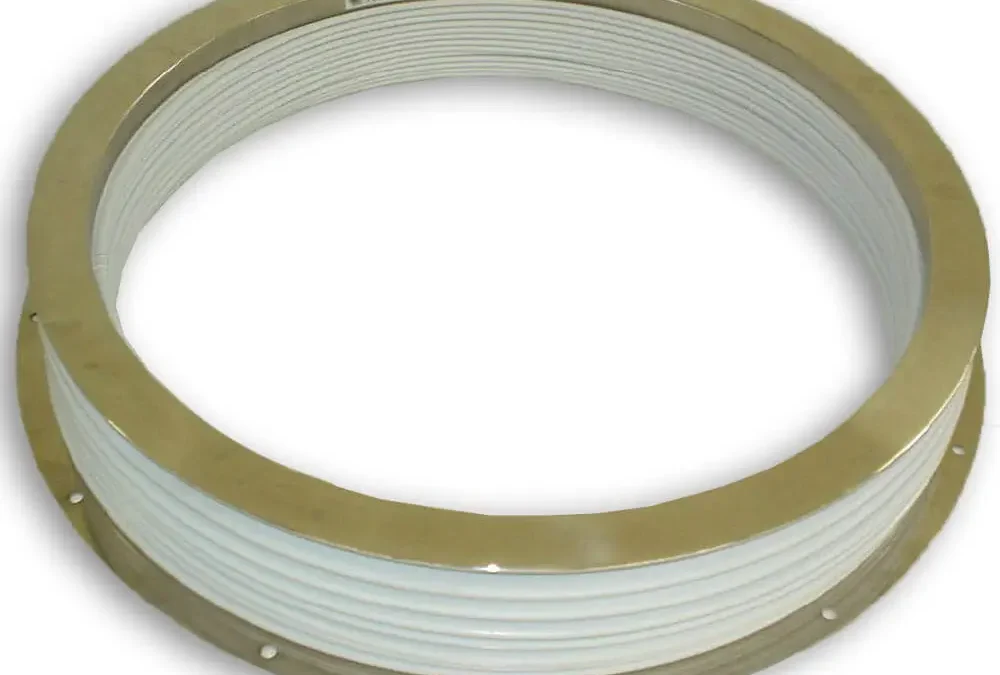

Clean Room Bellows

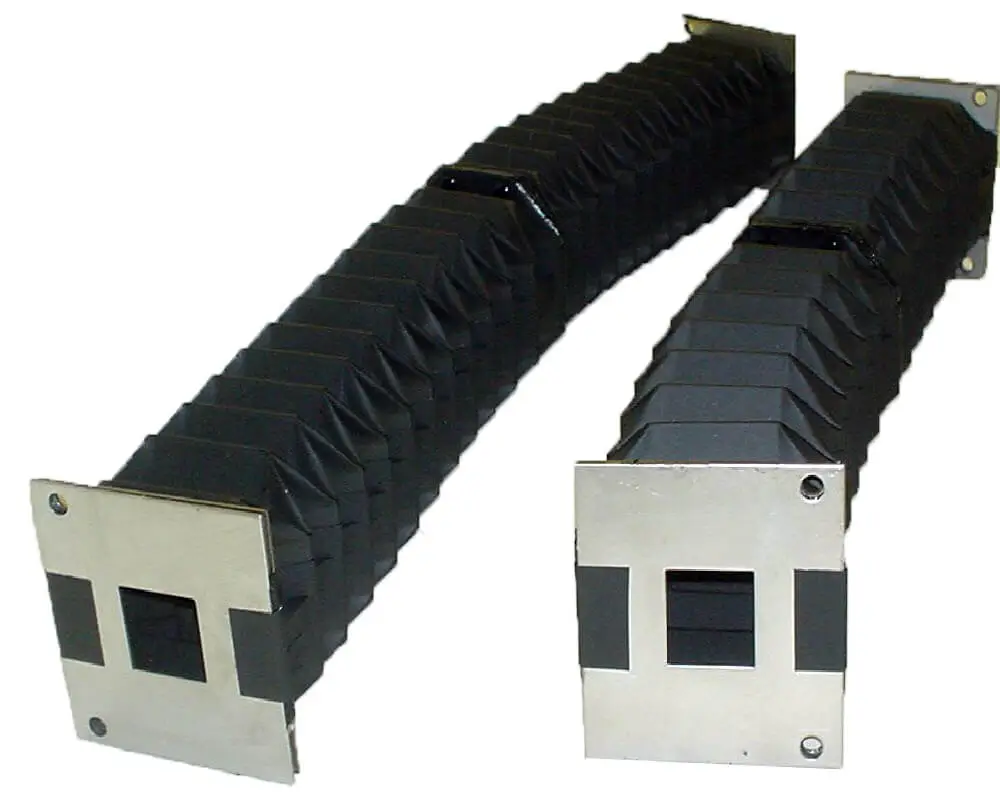

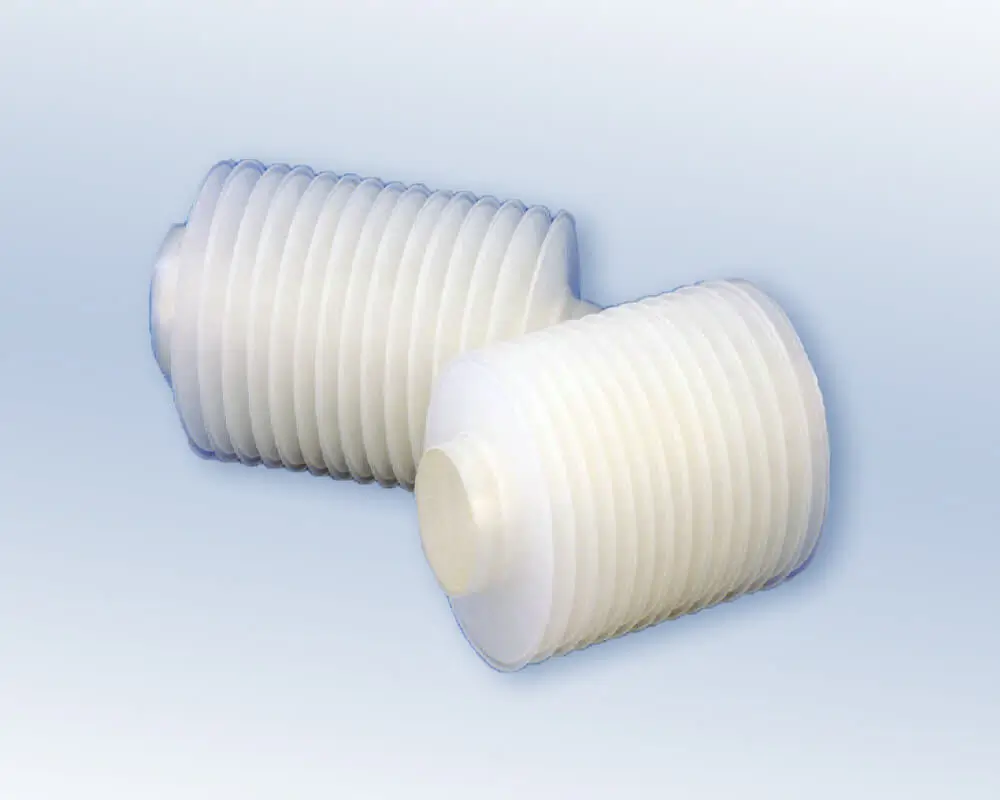

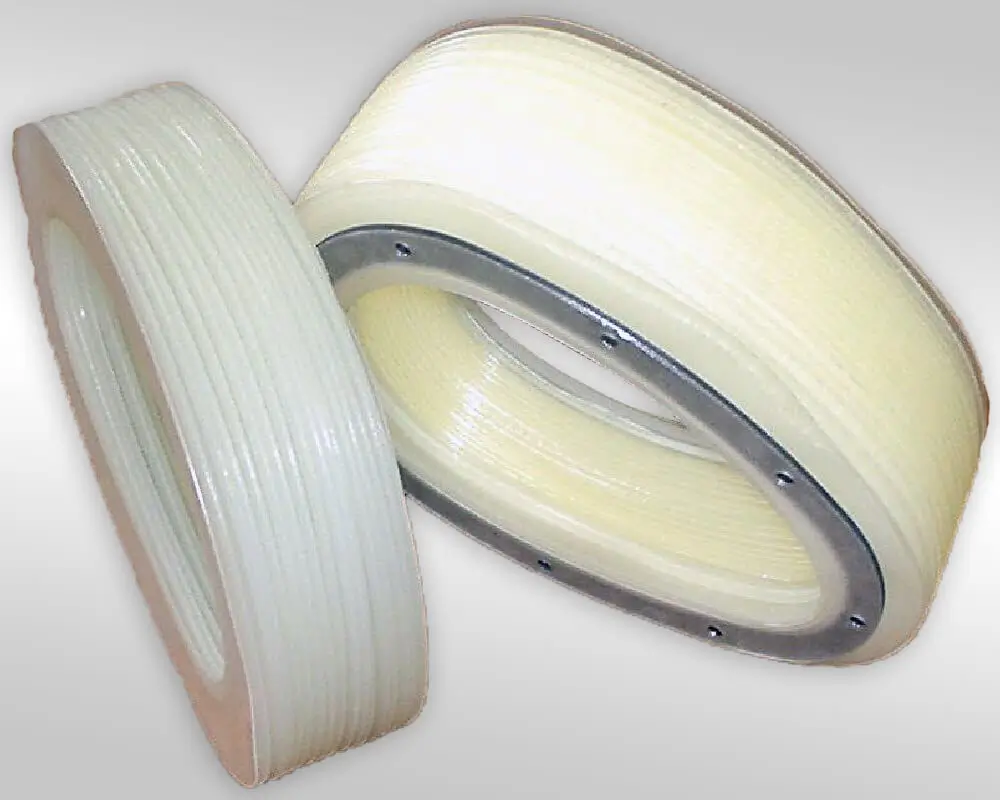

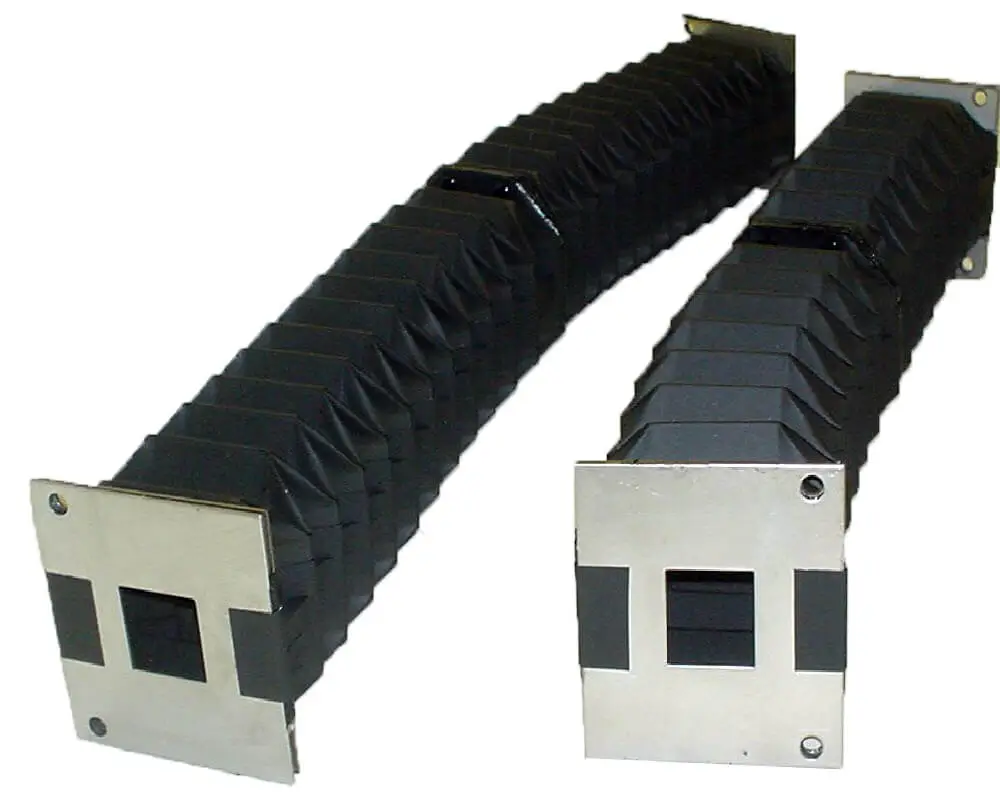

Purity is one of the important requisites of the process industry. Due to the raising awareness in the purity field, the industry focuses on controlling manufacturing processes to prevent technical components or equipment from being contaminated. At Nabell USA Corp, we meet all these requirements by offering customized high-quality cleanroom bellows. Made from FDA approved grades of polyurethane coated nylon, polyurethane film and others, our bellows are used to protect various equipment against dust and avoid conflicts with other aspects of the manufacturing process.

Purity is one of the important requisites of the process industry. Due to the raising awareness in the purity field, the industry focuses on controlling manufacturing processes to prevent technical components or equipment from being contaminated. At Nabell USA Corp, we meet all these requirements by offering customized high-quality cleanroom bellows. Made from FDA approved grades of polyurethane coated nylon, polyurethane film and others, our bellows are used to protect various equipment against dust and avoid conflicts with other aspects of the manufacturing process. The company is known for short-times deliveries, without losing the quality of the product. Our vast industrial experience helps us assure clean room bellows are built to the performance requirements of the medical and other industries across the globe.

Specifications of Clean Room Bellows Offered By Nabell USA

As a prominent industrial manufacturer of clean room bellows, we have designed and delivered clean room bellows in various specifications. We narrow down some of the specifications of these bellows that helped us fulfill complex requirements with ease:

- Applied Processes: At Nabell, we manufacture clean room bellows through heat sealing, folding and RF welding. These methods have been adopted owing to the reliability that they impart to the bellows.

- Base Materials: The choice of material is important for the development of clean room bellows, as it must meet the purity guidelines set by OEMs as well as industry standards. We use polyurethane coated nylon, polyurethane film and other materials for the construction of these bellows. These materials can easily meet the requirements of clean room applications.

- Material Thickness: The bellows can be provided in a material thickness of 0.2mm to 0.54 mm.

- Colors: The color of clean room bellows will vary depending on the material chosen for construction. You can always let us know any specific color requirements. We will use our stock colors to develop these bellows and may be able to offer custom colors.

- Packaging: Although we take the utmost care during manufacturing, the choice of the right packaging is important during delivery. We allow clients to choose the right packaging option for their clean room bellows.

- Delivery Times: Owing to our experience and technology investments, we assure the fastest delivery times in the industry, ie, 4-5 weeks with Rush Orders as a possibility.

- File Types Accepted: We can accept the drawings of bellows in any of the formats such as DWG, DXF, STEP, and Native Solid WORKS.

- Tooling Costs: In general, we do not charge any tooling fees.

Certifications and Standards

- ISO 9001:2015

- UL94-VTM0 test standard for wire insert bellows

Achieving client satisfaction of the utmost importance for us. We do not differentiate them based on the number of orders received. We provide personal attention to every client. This has helped us become one of the leading clean room bellows manufacturers in the US. Nabell takes pride in its team comprising some of the best bellows manufacturing experts in the country. They have not only been instrumental in building the company but have helped customers from healthcare and other industries to develop the clean room bellows for their applications. Do you have any confusion regarding the right material specifications for your clean room bellows or medical bellows? Our experts are ready to help you.

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Perforation Fold, RF Welding |

| Material Thickness | 0.2mm ~ 0.54mm |

| Base Material Selection | Polyurethane coated Nylon, Polyurethane film |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Industry for Use | Clean Room, Medical and others |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

Clean Room Bellows Quote Request Form

Clean Room Bellows Quote Request Form