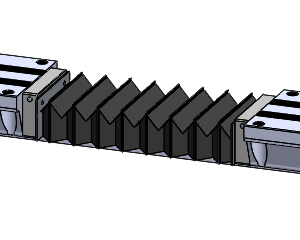

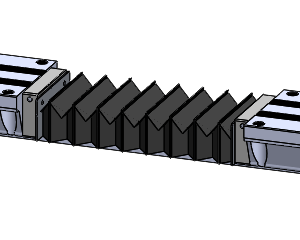

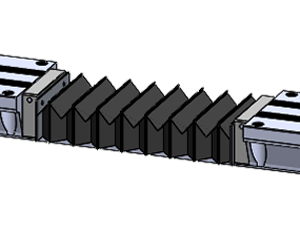

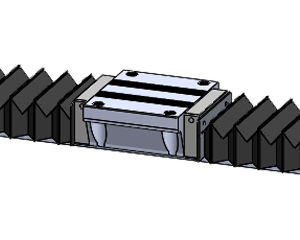

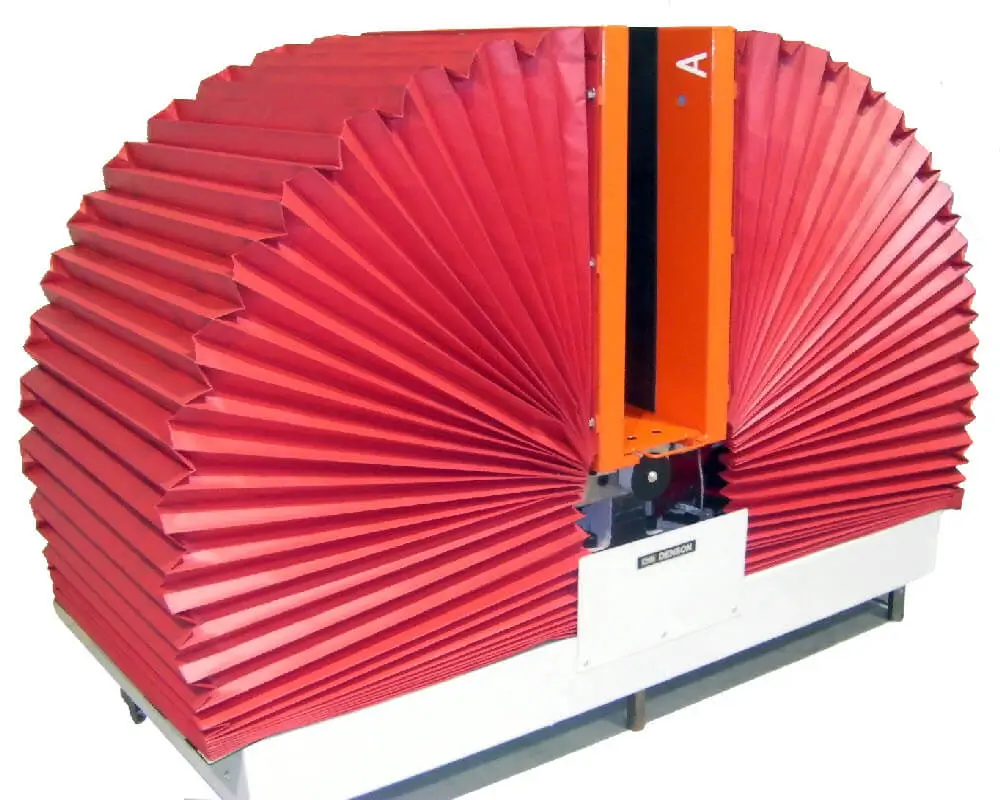

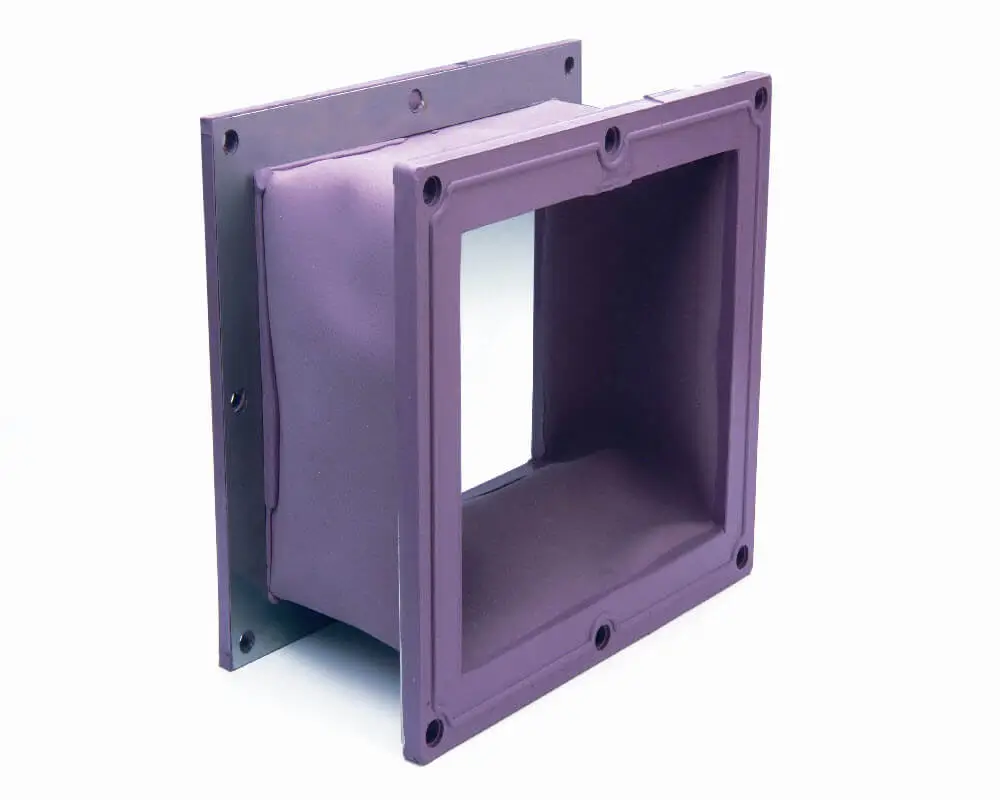

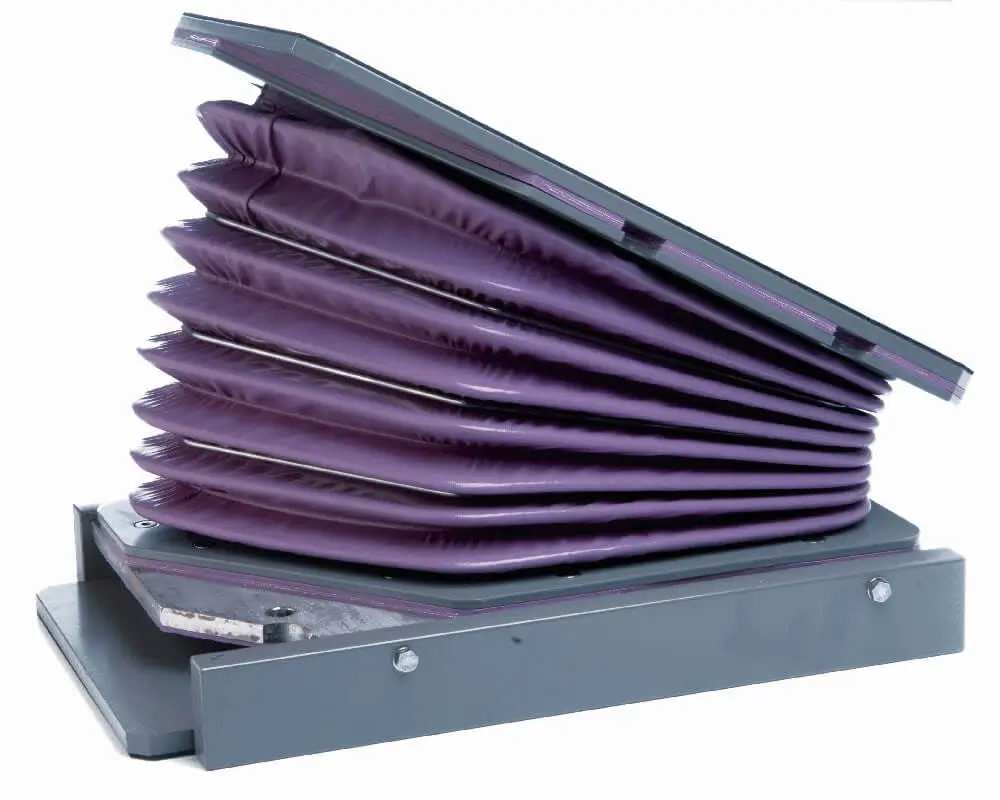

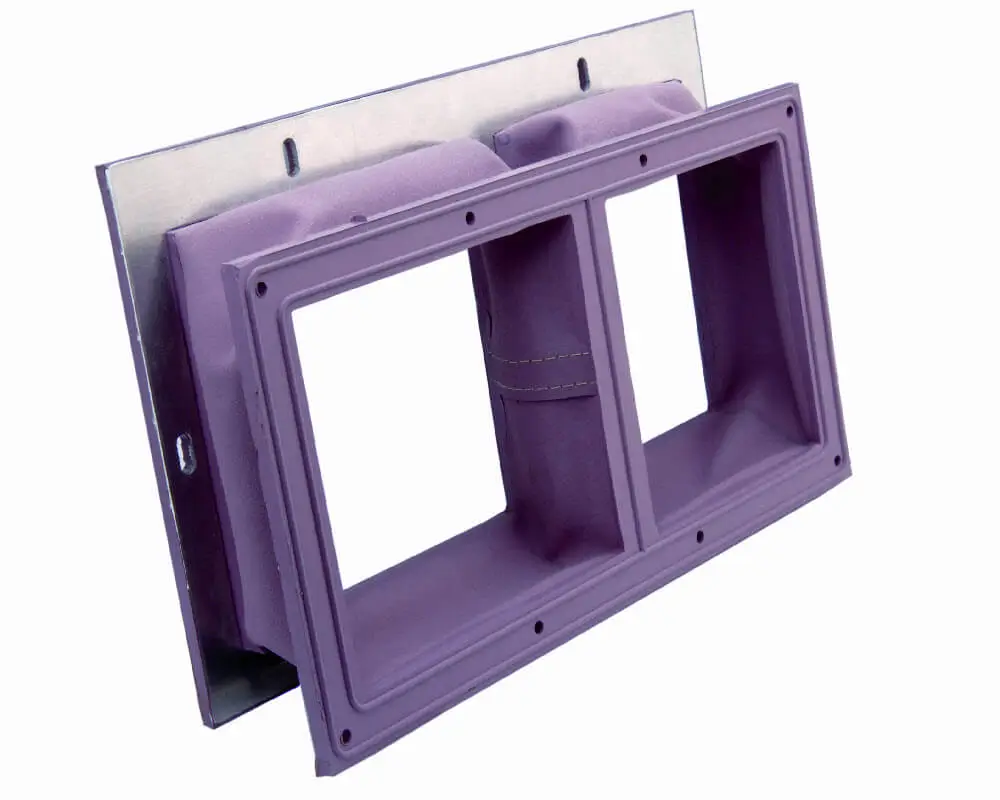

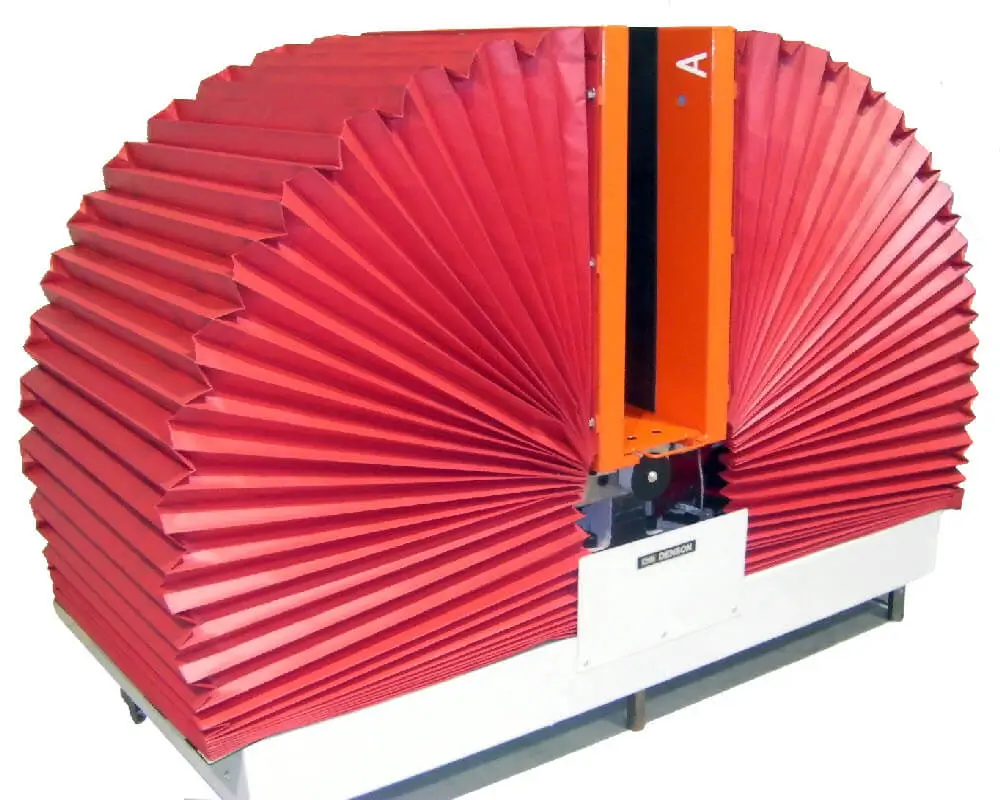

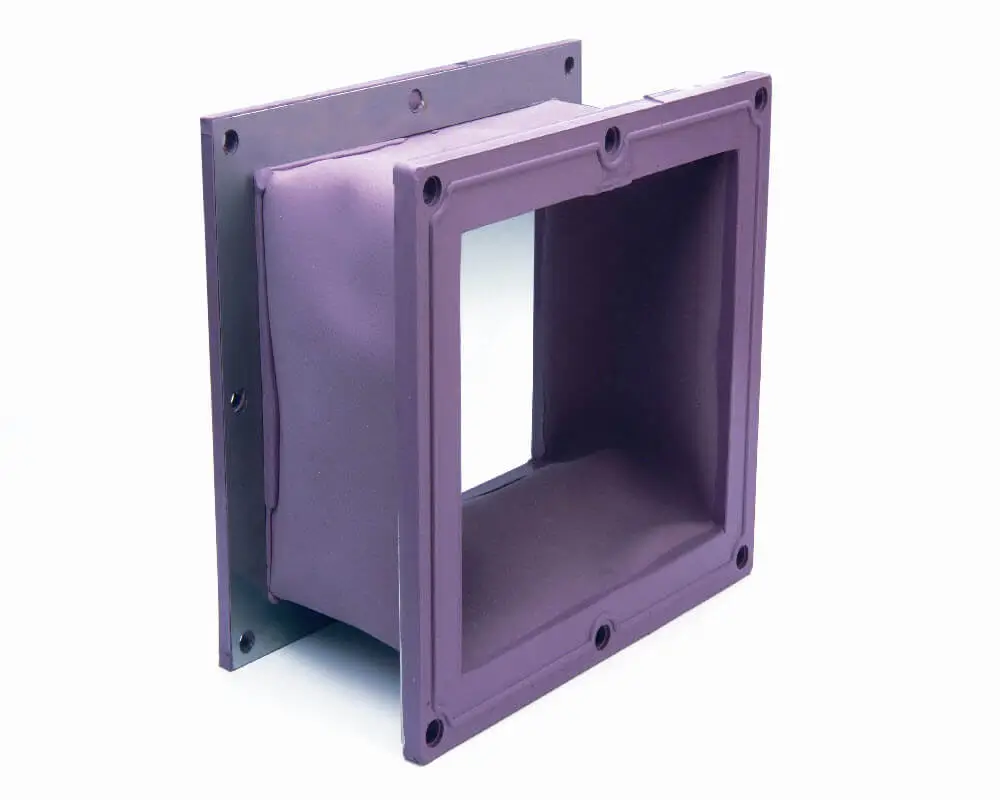

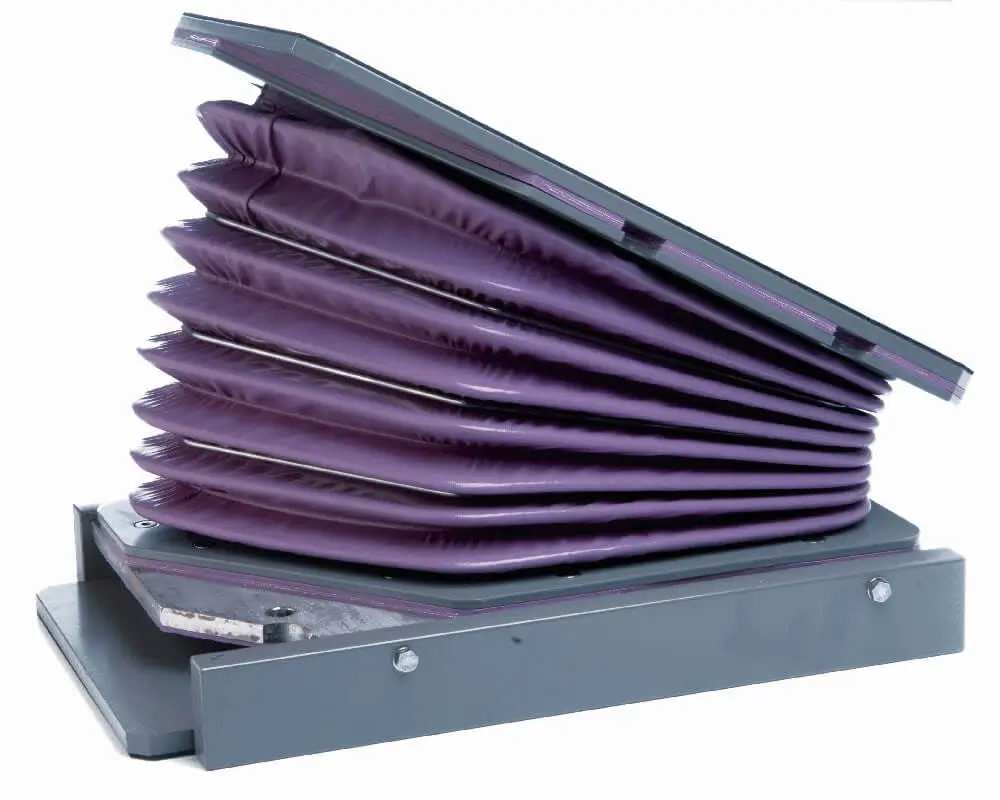

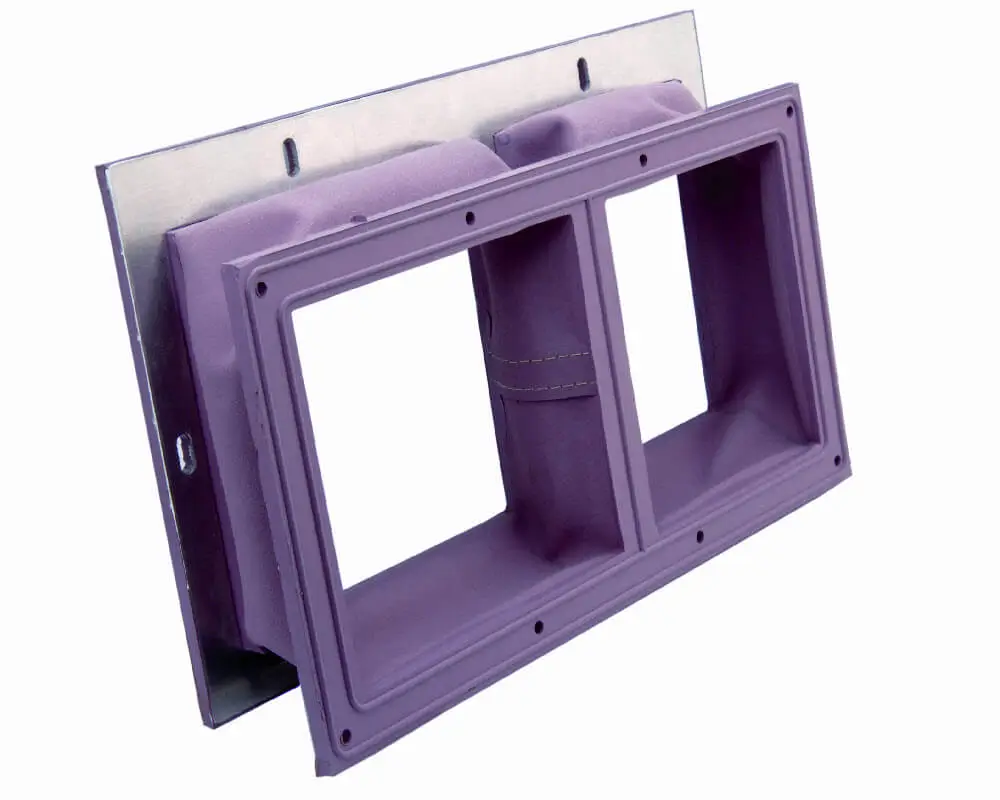

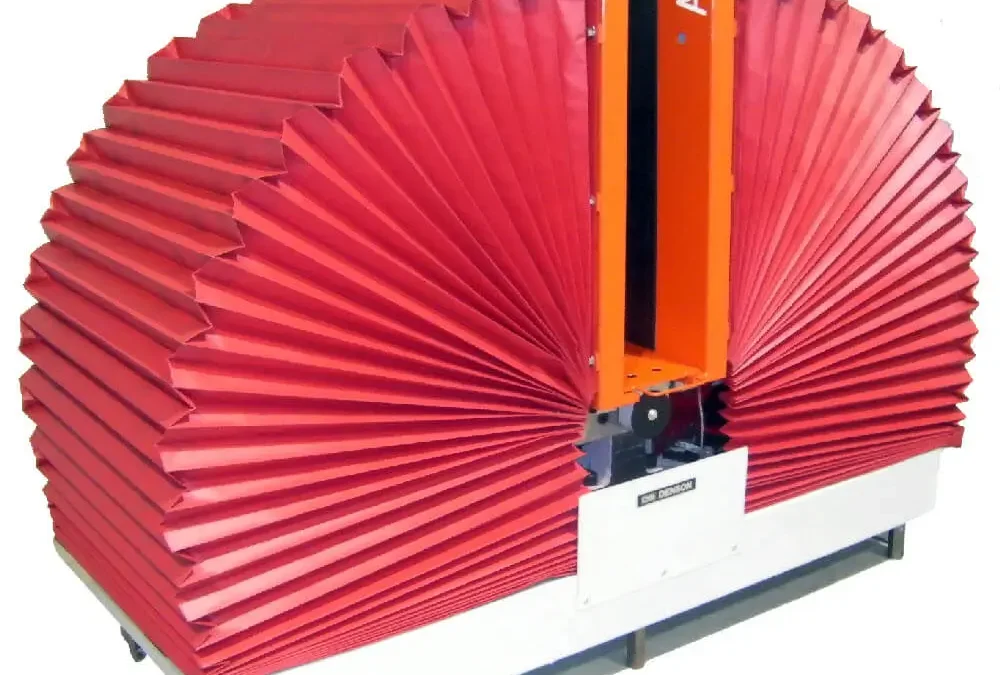

Enclosed Bellows

Enclosed bellows are used to improve human-machine safety and machine uptime. At Nabell USA, we provide enclosed bellows in varied dimensions and precision made to your requirements. Widely used for many applications from machine shafts and laser cutting applications to scissor lifts. Our enclosed bellows, made from durable, cut and tear resistant material, assure reliable service in outdoor and severe environments. With ultra-modern tools, machinery and manufacturing methods, we bring you top-notch enclosed bellows that are aesthetic, clean, uniform in appearance.

Specifications of Enclosed Bellows Provided by Nabell USA

We possess the expertise and experience to accommodate your requirements. The following are the capabilities we own when it comes to the making of enclosed bellows:

- Applied Processes: Nabell has a team of skilled personnel who are experts in making RF welded, Perforated Fold, Sewn Shape, and Combination Fold, Thermal Welded, and Wire Insert bellows.

- Base Materials: At Nabell, we use durable, coated fabric materials in the production of enclosed bellows that can withstand dirt, oils, and chemicals. Our team is experienced in working with a wide range of materials such as Aluminized Kevlar, Polyurethane, Neoprene coated Nylon, Polyurethane coated Polyester, Silicone Fiberglass cloth, Polyurethane coated Nylon, preoxydized Kevlar, Polyurethane coated Nomex, and PVC coated Polyester.

- Material Thickness: We can provide custom enclosed bellows in material thicknesses 0.2mm ~ 1.17mm.

- Colors: We can manufacture bellows using flame retardant materials in aesthetically pleasing colors. The colors will vary depending on the type of material chosen.

- File Types Accepted: Our innovative approach enables us manufacture enclosed bellows based on the drawings provided in DWG, DXF, STEP, and Native SolidWORKS formats.

- Tooling Costs: The tooling costs are zero for most projects.

- Packaging: We can deliver enclosed bellows in any packaging requested by the client.

Applications of Enclosed Bellows

With diverse product offering and a customer responsive sales philosophy, we meet our customers’ most stringent needs in short turnaround time. Leveraging our several years of experience, we offer unique designs to solve the requirements of industrial needs. A few amongst the application examples of our range of enclosed bellows are:

- Laser cutting equipment

- Ball screw protection

- Drive Protection

- Hydraulic Cylinders

Certifications

As a reputed enclosed bellows manufacturer, we are endeavored to meet the quality expectations set by our customers. The offered products are manufactured under expert supervision to maintain their high performance characteristics. Every stage of production is put to stringent quality checking, which enables Nabell to provide bellows with good mechanical properties. The following are the certifications and compliances we adhere to while manufacturing enclosed shaped bellows.

Certifications

- ISO 9001:2015

Compliances

- UL94-VTM0 test standard for wire insert bellows

With an expanded product portfolio and reduced lead times, we constantly improve our service and product performance. Next time, when you demand customized enclosed bellows, look no further than Nabell USA Corporation. As our products are appreciated for being dimensionally accurate and durable, you can feel confident choosing us to meet your requirements. With expert customer assistance, we will be happy to assist you throughout the production process.

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Thermal Welding, RF Welding, Perforated Fold, Combination Fold, Sewn Shape, Wire Insert |

| Material Thickness | 0.2mm ~ 1.17mm |

| Base Material Selection | Aluminized Kevlar, Polyurethane, Neoprene coated Nylon, Polyurethane coated Polyester, Silicone Fiberglass cloth, Polyurethane coated Nylon, preoxydized Kevlar, Polyurethane coated Nomex, PVC coated Polyester |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

| Industry for Use |

|

Enclosed Bellows Quote Request Form

Enclosed Bellows Quote Request Form