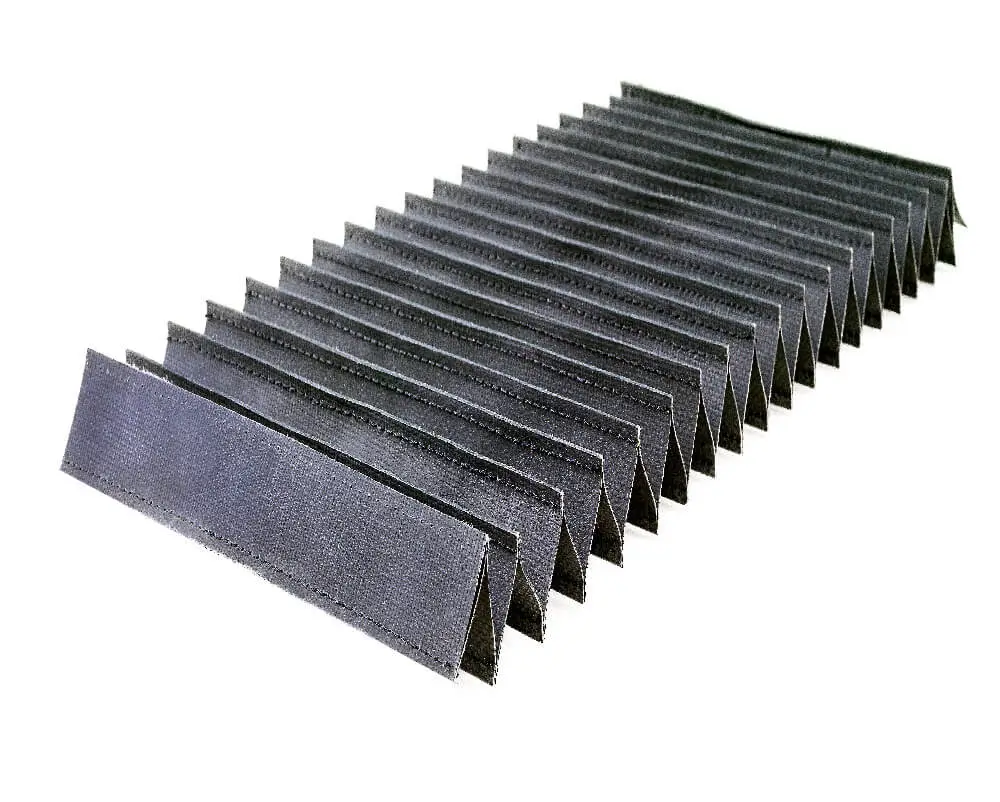

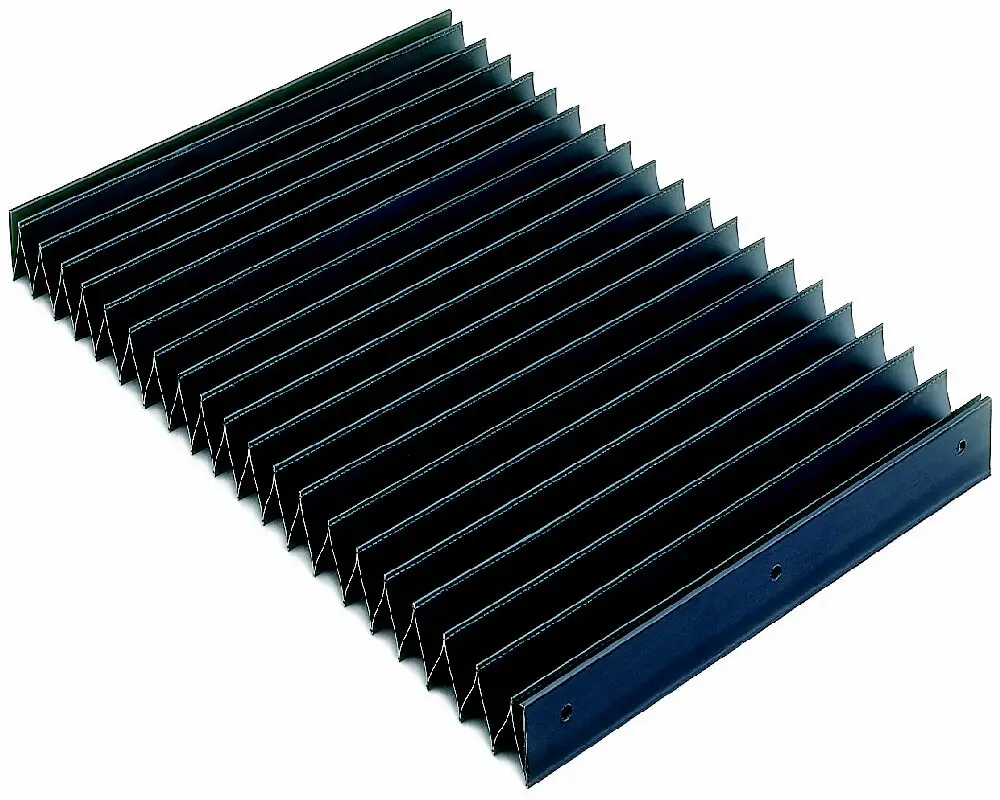

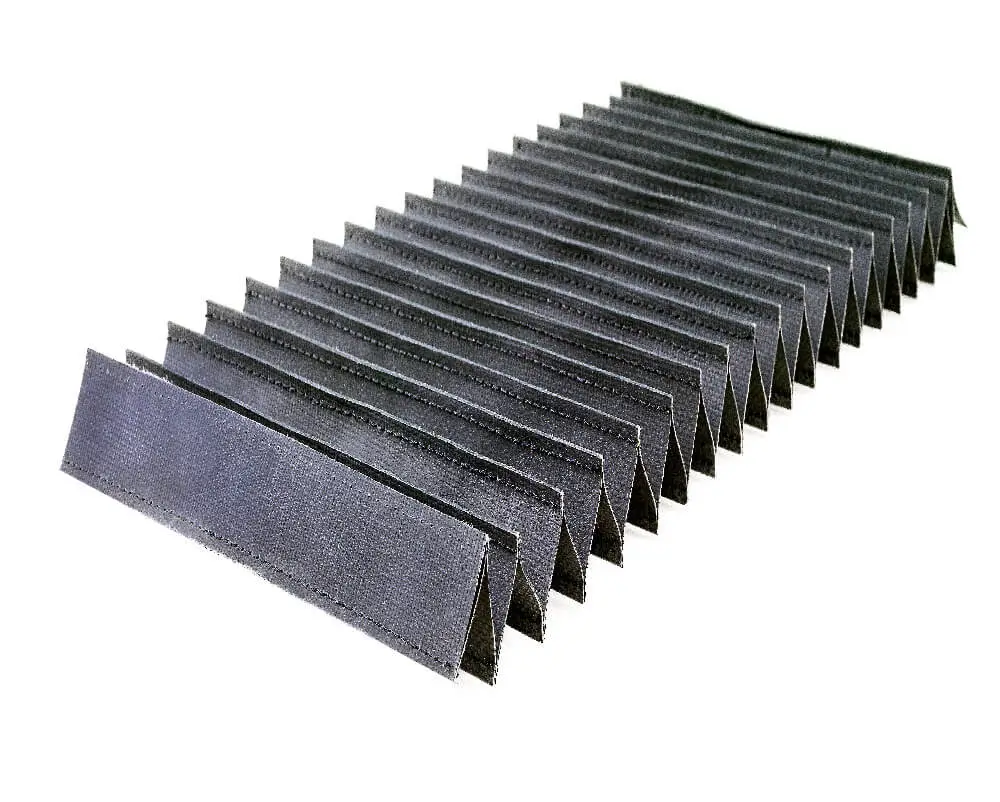

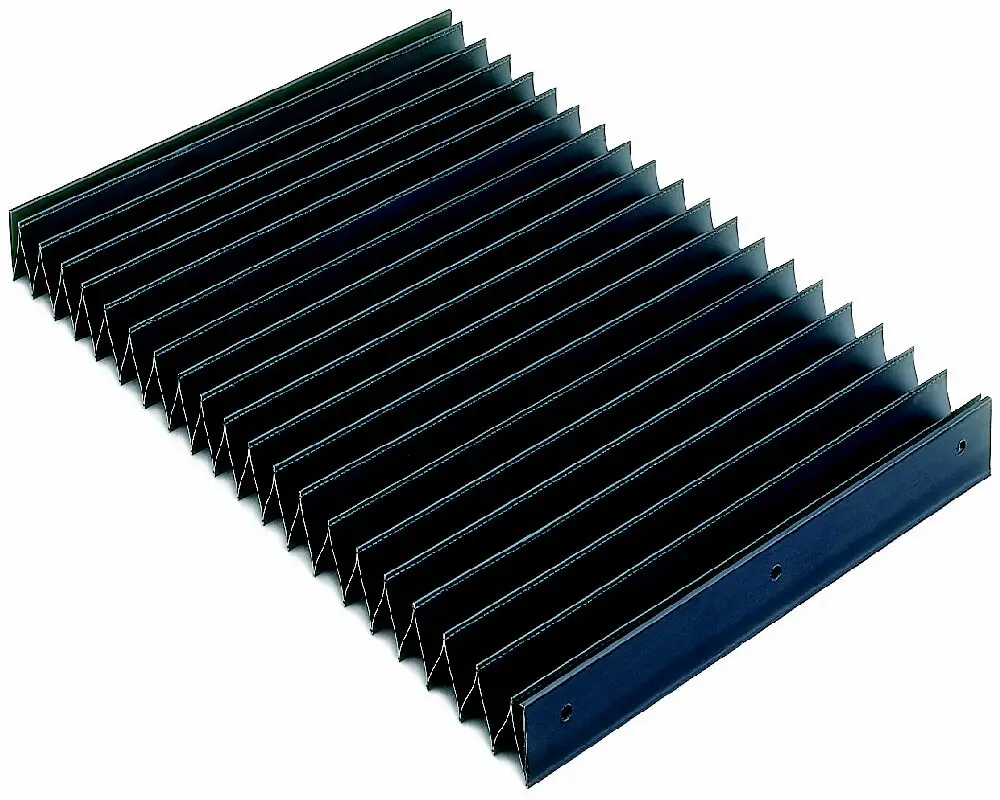

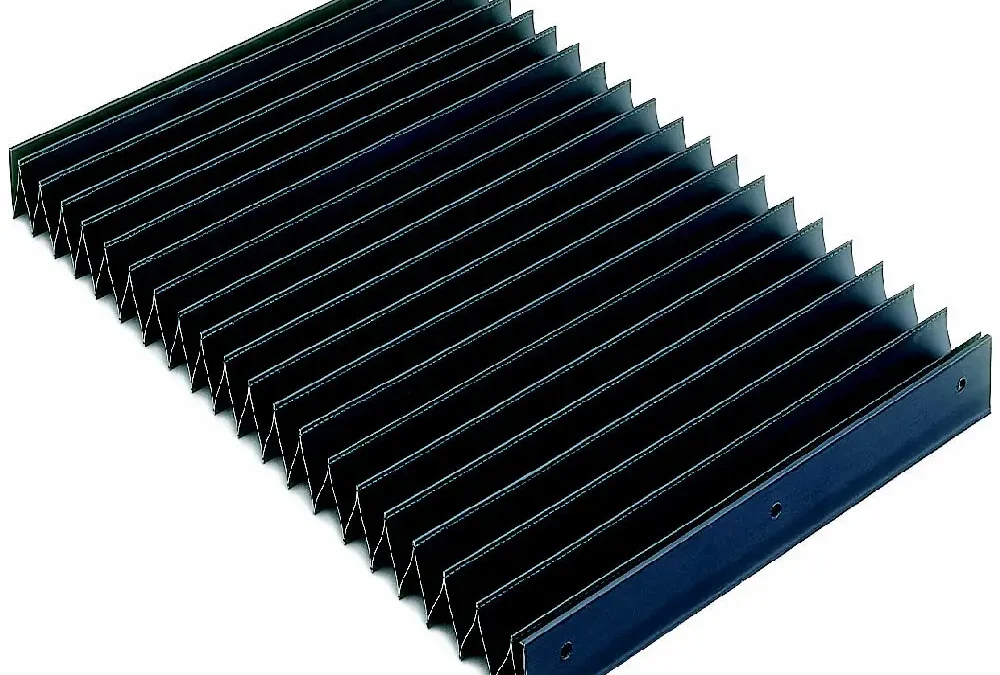

Flat Bellows

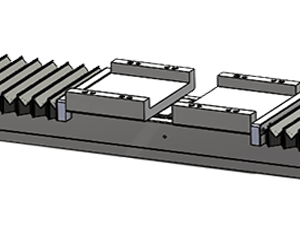

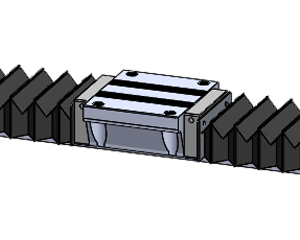

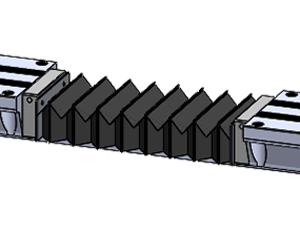

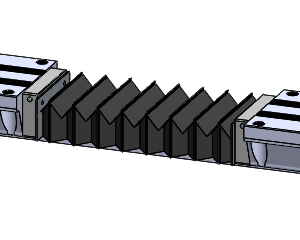

Flat bellows are used in various industries to shield or protect machines and equipment from abrasion and contamination. Flat bellows are not just meant for flat surfaces but also for vertical ones. One can use stiffeners to hold flat bellows in the required shape. They help prevent debris accumulation and act like a screen guard of the surface they cover, especially when the machines or tools move at a certain axis. At Nabell USA Corp, we make flat bellows for machine tools from a variety of materials, and in custom specifications. Our experience and focus on quality help us assure the custom flat bellows are built according to the performance requirements of our customers from various industries.

Flat bellows are used in various industries to shield or protect machines and equipment from abrasion and contamination. Flat bellows are not just meant for flat surfaces but also for vertical ones. One can use stiffeners to hold flat bellows in the required shape. They help prevent debris accumulation and act like a screen guard of the surface they cover, especially when the machines or tools move at a certain axis. At Nabell USA Corp, we make flat bellows for machine tools from a variety of materials, and in custom specifications. Our experience and focus on quality help us assure the custom flat bellows are built according to the performance requirements of our customers from various industries.

Specifications of Flat Bellows Provided by Nabell USA

As a manufacturer of industry-leading flat bellows and protective covers for machines and equipment, we offer a variety of bellows, way cover repairing, and more. All of these products are made in various specifications and configurations, and using different processes. These are some capabilities that help us meet the exact requirements:

- Applied Processes: We manufacture flat bellows utilizing various processes such as thermal welding, RF welding, perforated folding, combination folding, and sewn shapes.

- Material Thickness: The thickness of these products is between 0.2mm and 0.94mm.

- Base Material Selection: We manufacture flat bellows from a variety of materials that include aluminized Kevlar, polyurethane, neoprene-coated nylon, polyurethane-coated polyester, silicone fiberglass cloth, polyurethane-coated nylon, preoxydized Kevlar, polyurethane-coated Nomex, and PVC-coated polyester.

- Color: It varies depending on the chosen base material.

- Packaging: Our flat bellows are packaged and delivered according to customers’ specifications

- Delivery Time: Generally, we deliver the products in four to five weeks.

- Drawing Type Accepted: The design file formats we accept include DWG, DXF, STEP, and Native SolidWORKS.

- Tooling Cost: Generally, we do not charge any tooling costs from the customers.

Applications of Flat Bellows

Our high-quality flat bellows have applications in various industrial segments. These are economical options to get rid of particles, cutting oils and lubricants, and hot chips. To be able to determine if you require flat bellows, you need to check certain factors such as exposure of your machines to dust, contamination, moisture, welding, sparking, chemicals, extreme temperatures, and so on. Here are a few application areas of flat bellows listed:

- Machine tools

- General industrial equipment and machines

- Clean room and medical

- Optical

- Linear motion equipment

- Drive protection

- Gantry protection

- Laser cutting

- Ball screw protection

Certifications and Standards

We, at Nabell, have developed an expertise in manufacturing custom flat bellows in the highest quality. Our following certification and standard show our commitment to quality.

- ISO 9001:2015

- UL94-VTM0 test standard for wire insert bellows

At Nabell USA Corp, we offer custom flat bellows for various applications. All our products are low on maintenance, made from the best of materials, and have absolutely no leakage issues. Our team comprises design engineers with a vast industry experience, who design innovative solutions that are cost effective, robust, and durable. Our experts help customers choose the right material, color, and dimensions and work with them right from ideation to the delivery phase making us one of the leading custom flat bellows manufacturers in the US.

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Thermal Welding, RF Welding, Perforated Fold, Combination Fold, Sewn Shape |

| Material Thickness | 0.2mm ~ 0.94mm |

| Base Material Selection | Aluminized Kevlar, Polyurethane, Neoprene coated Nylon, Polyurethane coated Polyester, Silicone Fiberglass cloth, Polyurethane coated Nylon, preoxydized Kevlar, Polyurethane coated Nomex |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Industry for Use | Machine tool,General industrial,Clean room,Medical,Optical,Linear Motion,Drive Protection,Way covers,Gantry protection,Laser cutting,Ball Screw Protection |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

Flat Bellows Quote Request Form

Flat Bellows Quote Request Form