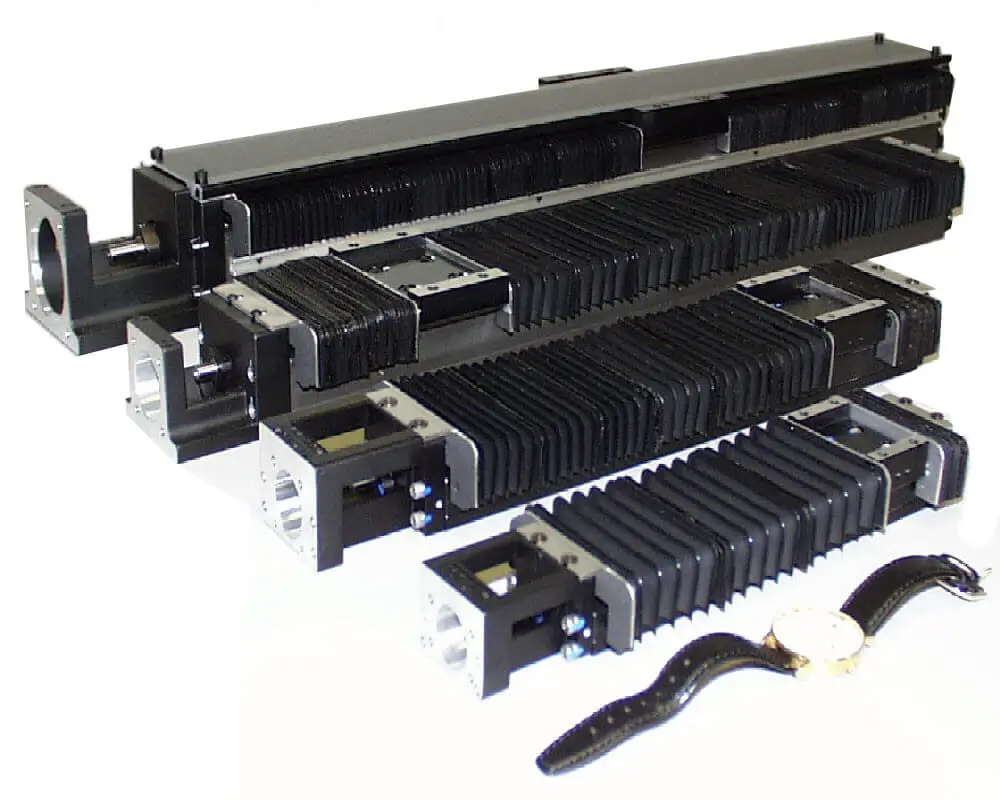

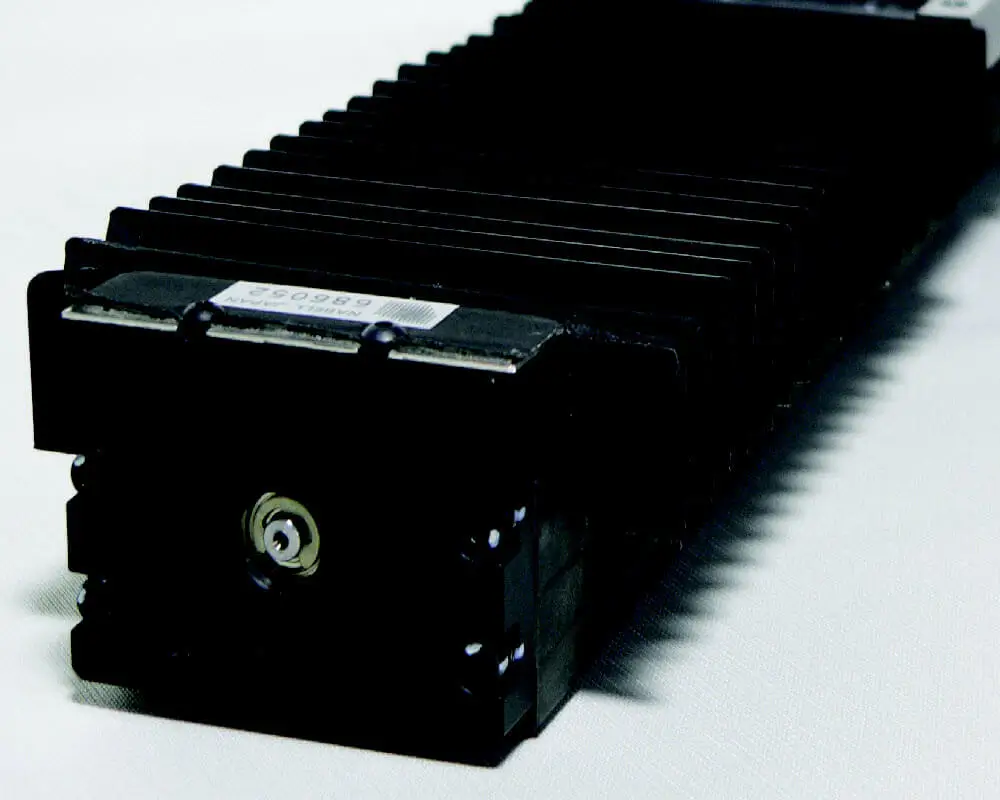

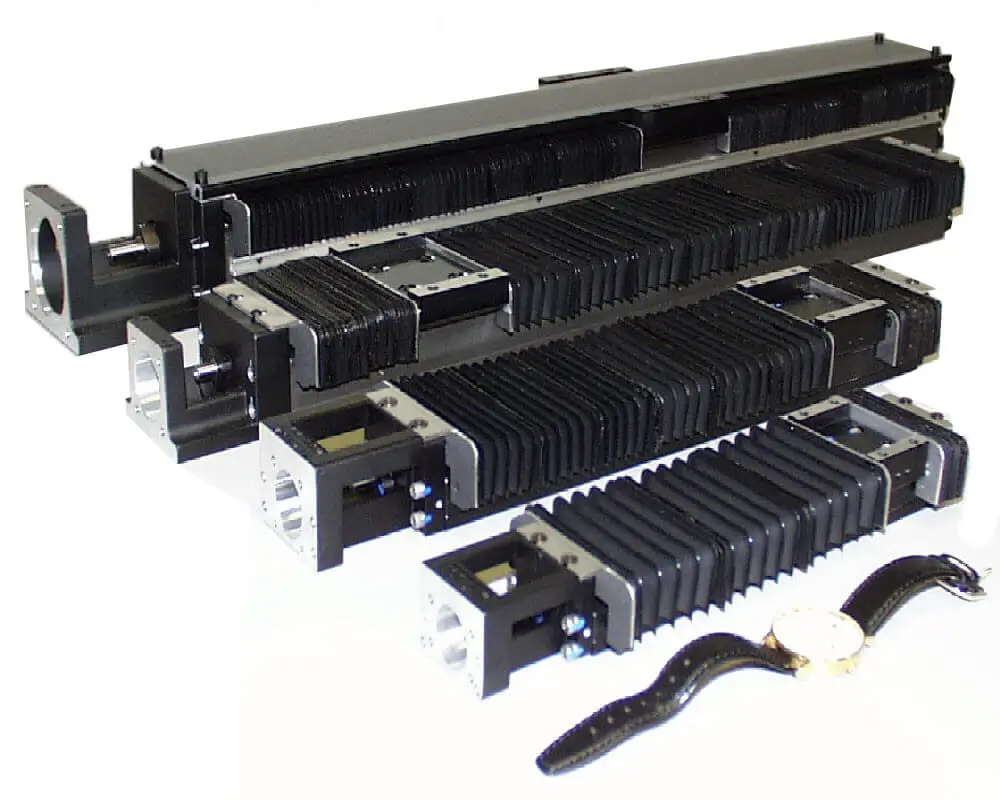

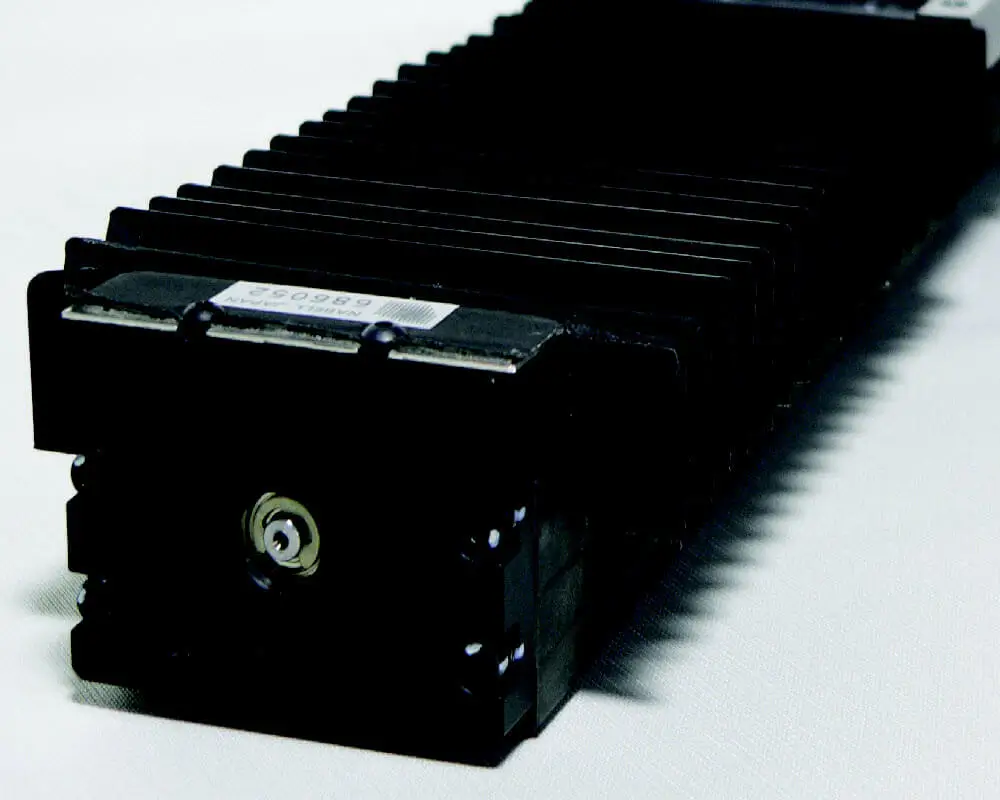

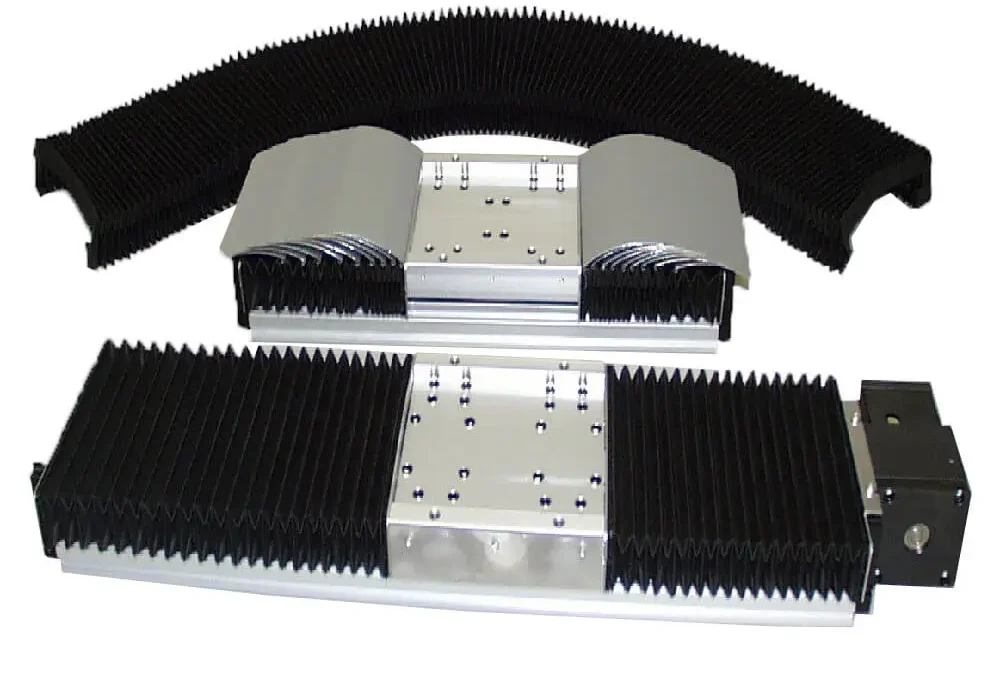

Linear Motion Bellows

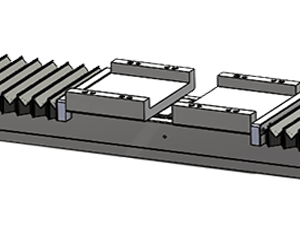

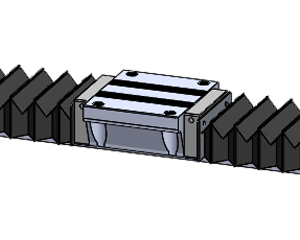

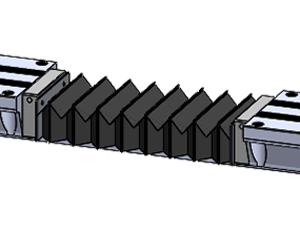

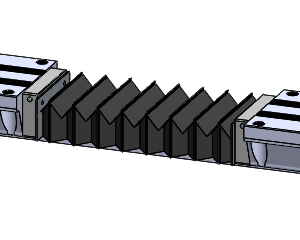

Linear motion bellows are required in various industries to protect linear devices from contamination and dust. They, in a way, help maintain the performance levels of such devices. We offer linear motion bellows in eight different shapes. At Nabell USA, we provide custom linear motion bellows that are specially designed to overcome a common drawback observed. Our bellows do not raise themselves off the rail while being compressed. They are designed to withstand extremely hot temperatures, as high as 900 degrees Fahrenheit.

Linear motion bellows are required in various industries to protect linear devices from contamination and dust. They, in a way, help maintain the performance levels of such devices. We offer linear motion bellows in eight different shapes. At Nabell USA, we provide custom linear motion bellows that are specially designed to overcome a common drawback observed. Our bellows do not raise themselves off the rail while being compressed. They are designed to withstand extremely hot temperatures, as high as 900 degrees Fahrenheit. Also, they can be customized to suit a particular type of rail. To support the performance of our bellows in harsh conditions, we offer stainless steel customizable slat protectors. At Nabell USA Corp, we make linear motion bellows for machine tools in a vast range of specifications to suit customer requirements. Our focus on quality helps us meet the stipulated standards and client requirements when manufacturing linear motion bellows.

Specifications of Linear Motion Bellows by Nabell

Being a reliable manufacturer of machine tool accessories, we offer a variety of linear motion bellows. We offer all our products in various specifications and configurations. These are some factors that help us meet the requirement accurately:

- Applied Processes: The processes such as thermal welding, perforated folding, and combination folding are used to make our linear motion bellows.

- Material Thickness: The products are available in material thicknesses 0.2mm and 1.17mm.

- Base Material Selection: We manufacture linear motion bellows from a variety of materials that include polyurethane, aluminized Kevlar, silicone fiberglass cloth, neoprene-coated nylon, PVC-coated polyester, polyurethane-coated polyester, polyurethane-coated nylon, preoxydized Kevlar, polyurethane-coated Nomex.

- Color: The bellows can be availed in any color of your choice.

- Packaging: We pack and deliver linear motion bellows according to customers’ specifications.

- Delivery Time: Generally, the timeframe for delivering prototypes is four to five weeks depending on the requirements of the design.

- Drawing Type Accepted: We accept these design file formats: DWG, DXF, STEP, and Native SolidWORKS.

- Tooling Cost: There are no tooling costs.

Applications of Linear Motion Bellows Made at Nabell

Linear devices are equipped with various components, which are built strong for a long-term performance. However, they are not designed to avoid dust and contamination on their own. This is where linear motion bellows can help. Here, we have listed a few application segments where these bellows are used:

- Linear ball screws

- Linear rail guides

- Hydraulic and pneumatic applications

- Beamline filter positioning

- Linear carriages

- Automated equipment

Certifications and Standards

At Nabell, we have achieved proficiency in manufacturing and customizing linear motion bellows and more. We are ISO 9001:2015 certified for our quality management system to manufacture protective covers and bellows. We also have the UL94-VTM0 test standard for wire insert bellows certification.

At Nabell USA Corp, we are committed to providing high-quality bellows that are low on maintenance, robust, and without any leakage issues. Our team comprises design engineers with a vast industry experience, who design innovative solutions that are cost effective and long lasting.

Additional Information :

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Thermal Welding, Perforated fold, Combination Fold |

| Material Thickness | 0.2mm ~ 1.17mm |

| Base Material Selection | Aluminized Kevlar, Polyurethane, Neoprene coated Nylon, Polyurethane coated Polyester, Silicone Fiberglass cloth, Polyurethane coated Nylon, preoxydized Kevlar, Polyurethane coated Nomex, PVC Coated Polyester |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Industry for Use | Linear Motion, machine tool, general industrial |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

Linear Motion Bellows Quote Request Form

Linear Motion Bellows Quote Request Form