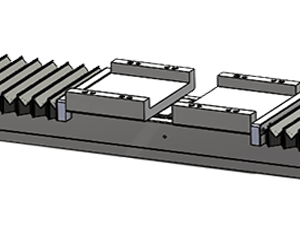

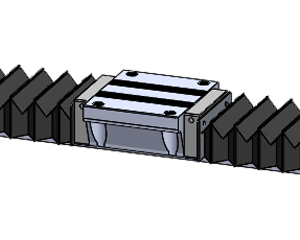

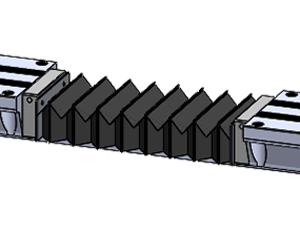

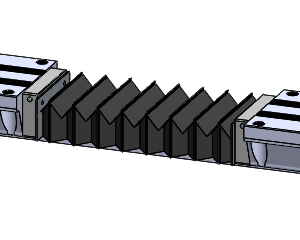

Laser Cutting Bellows

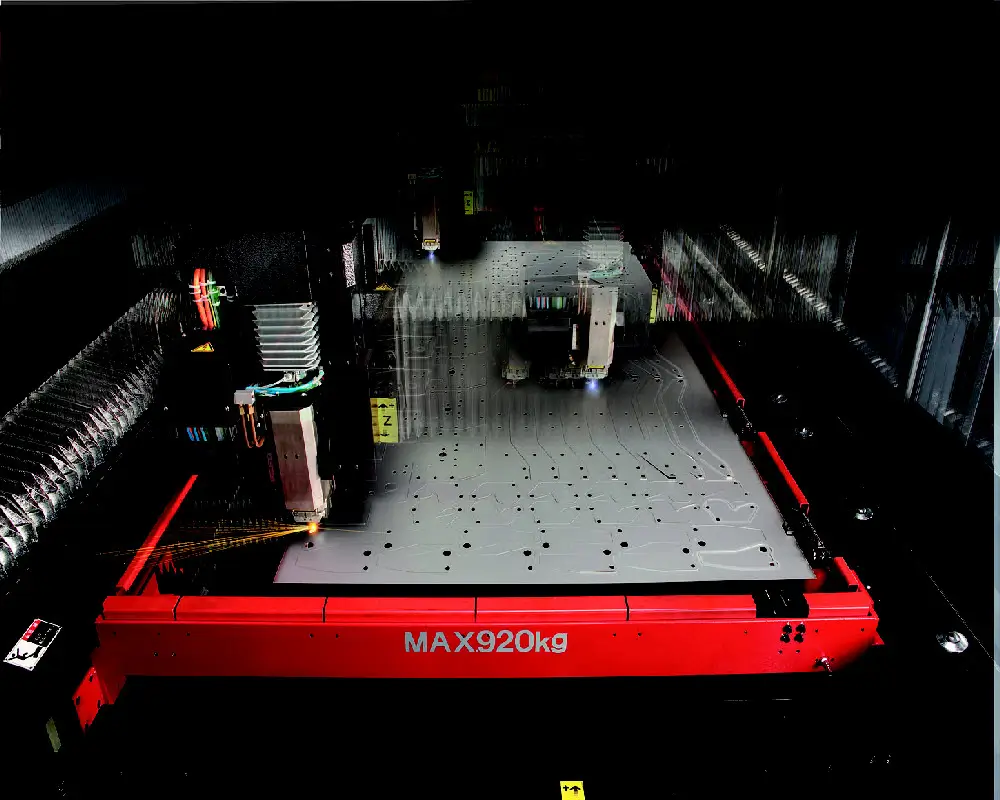

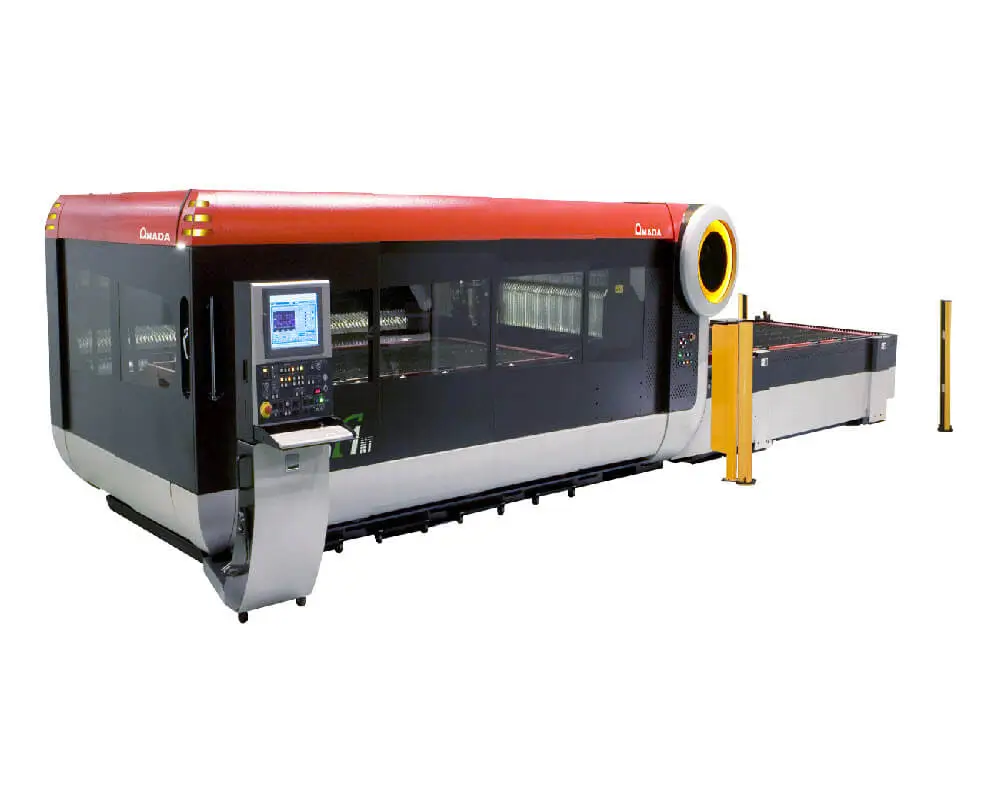

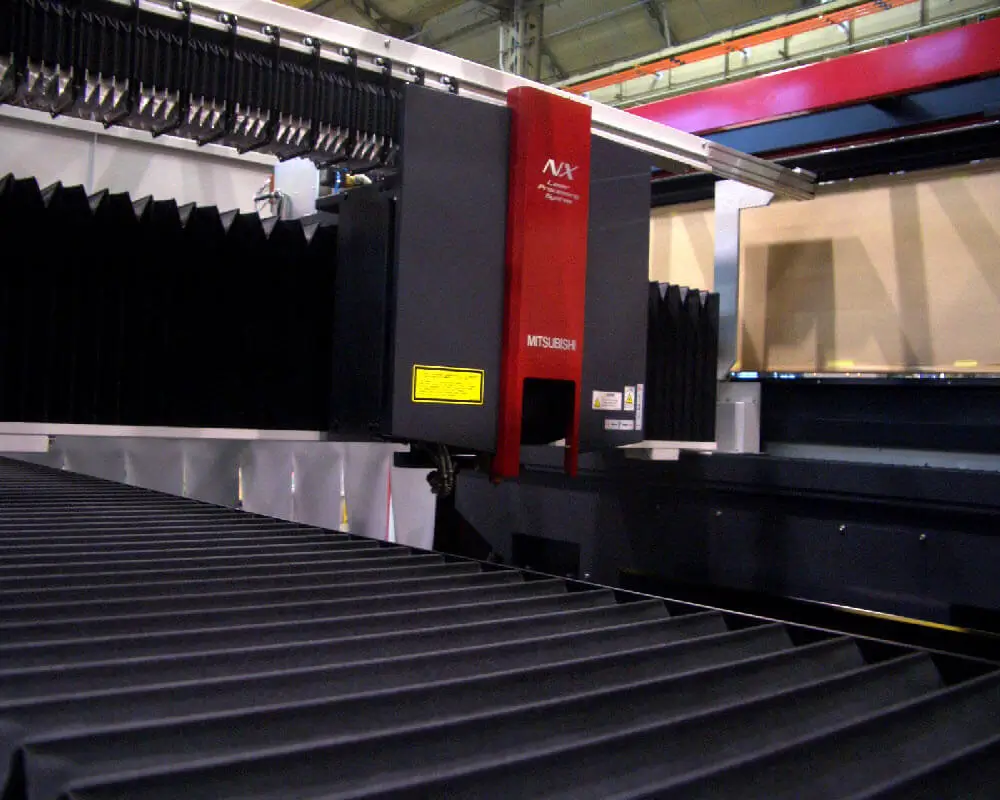

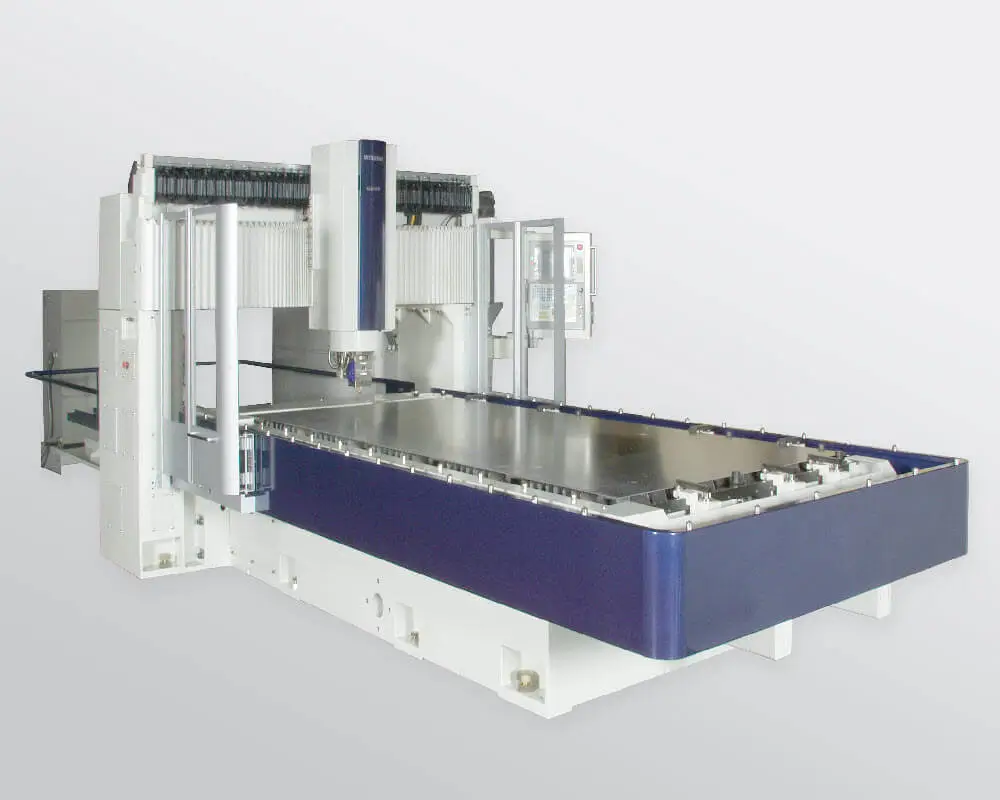

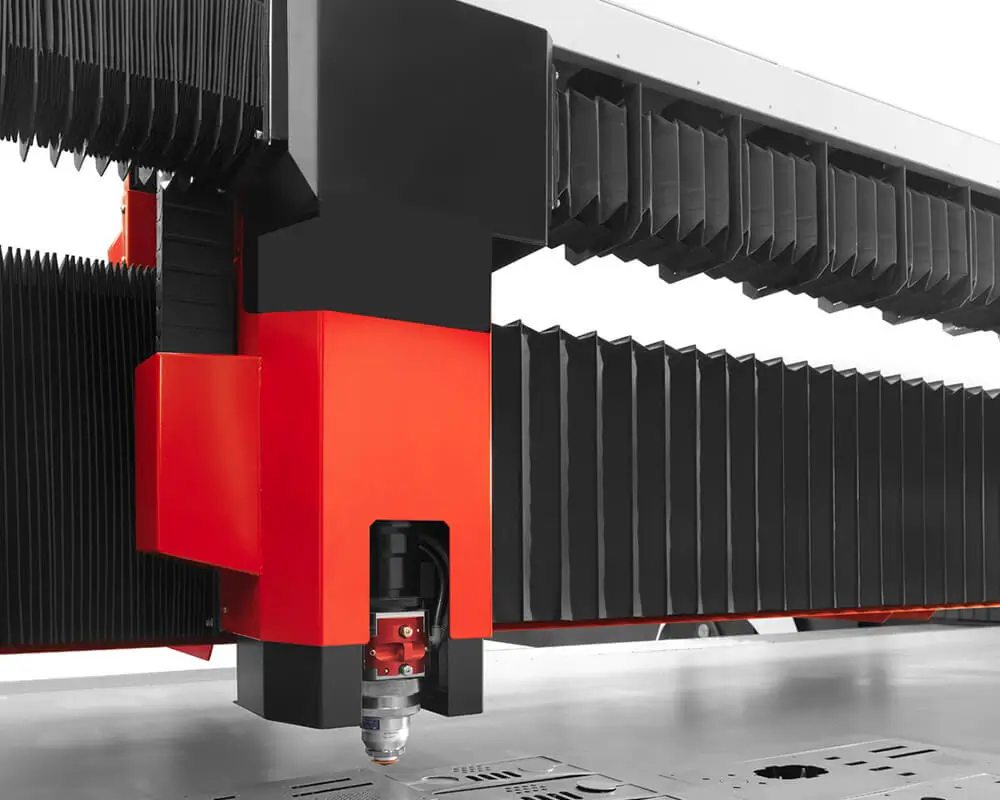

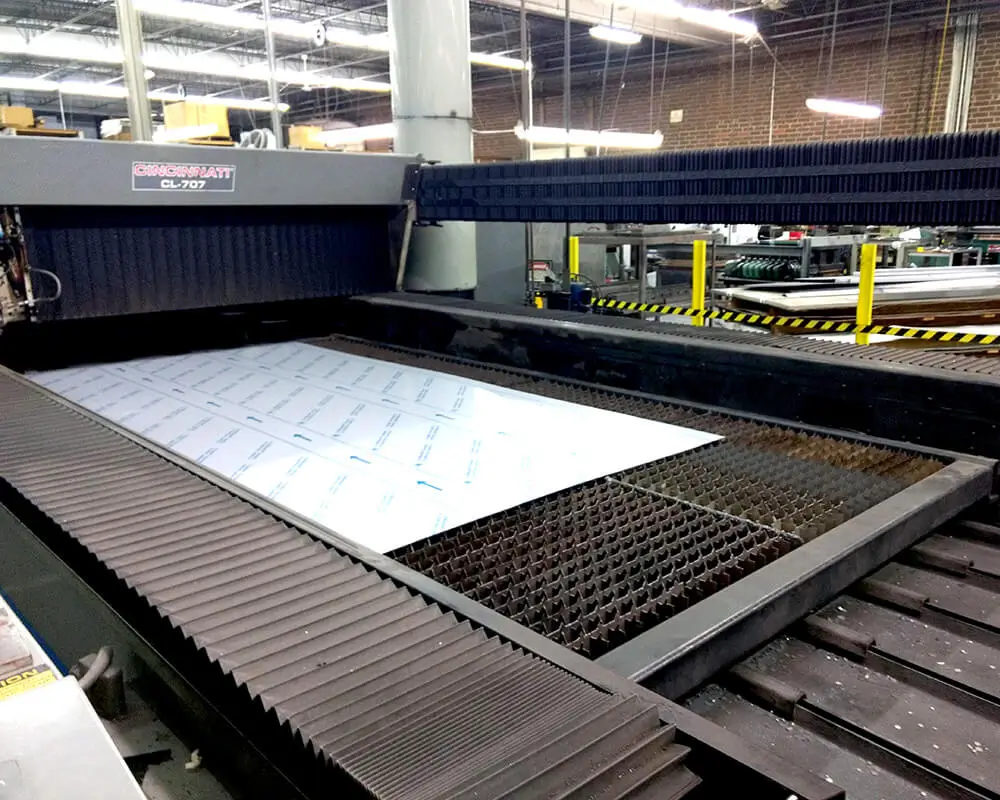

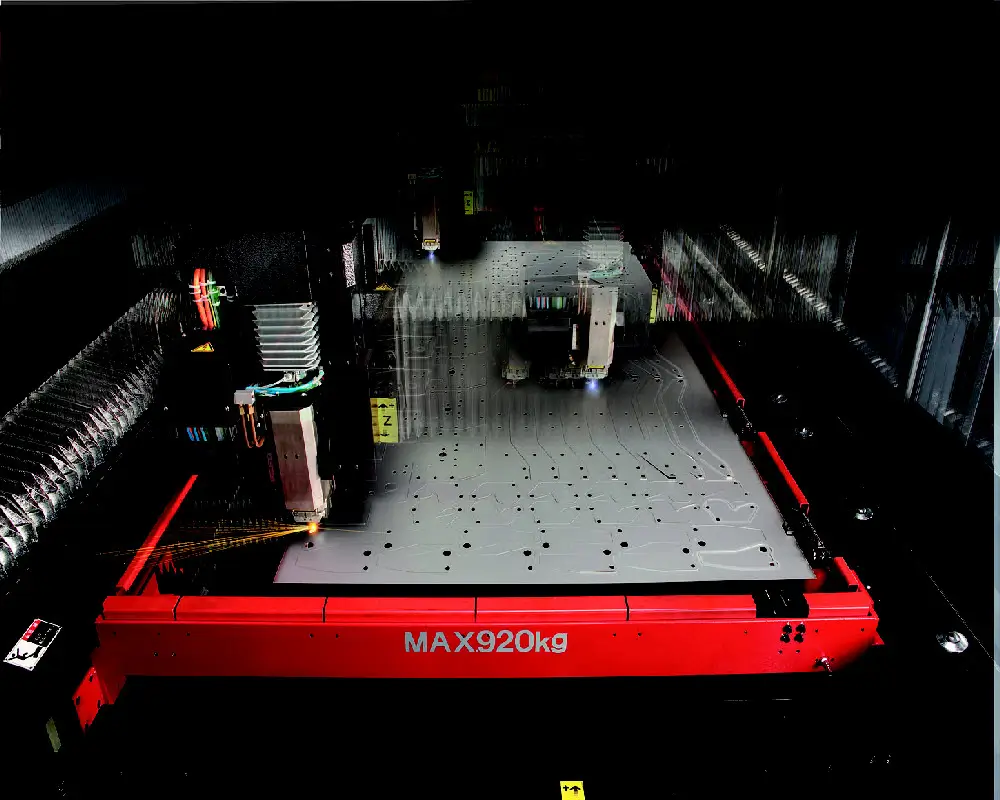

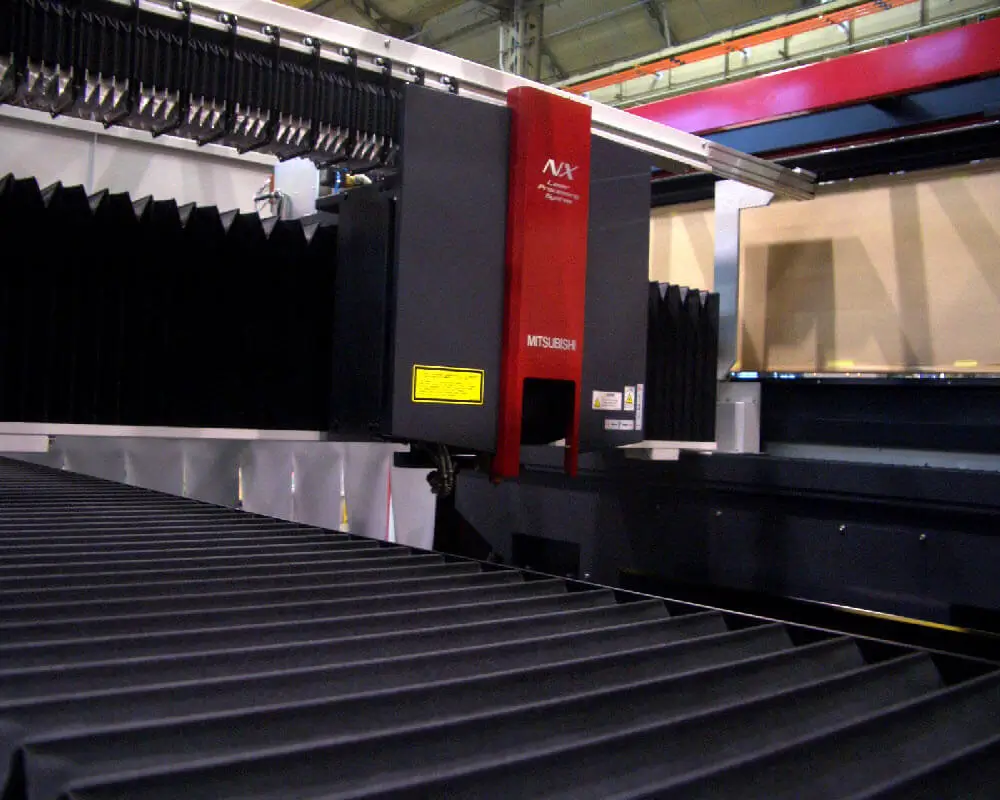

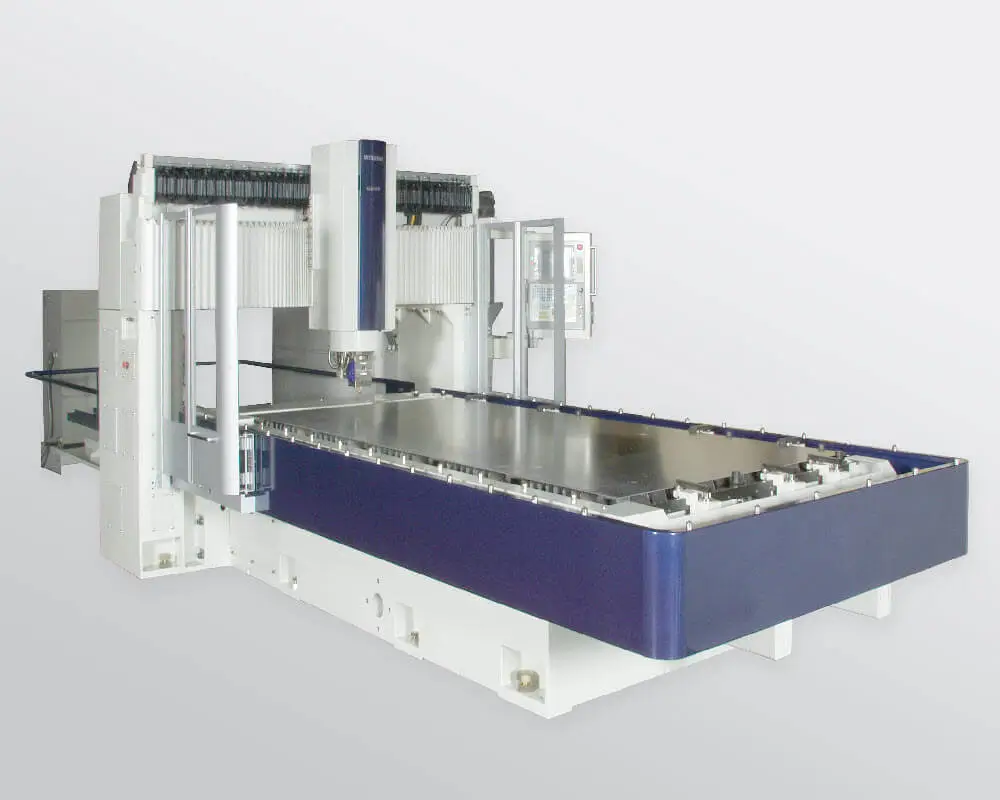

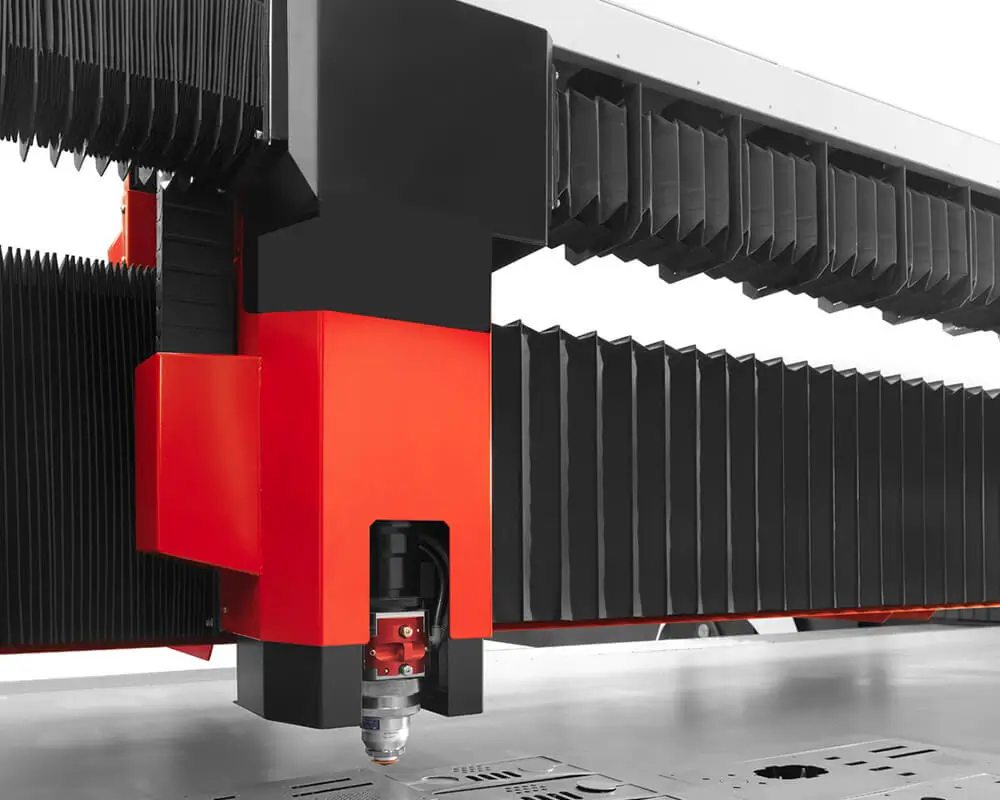

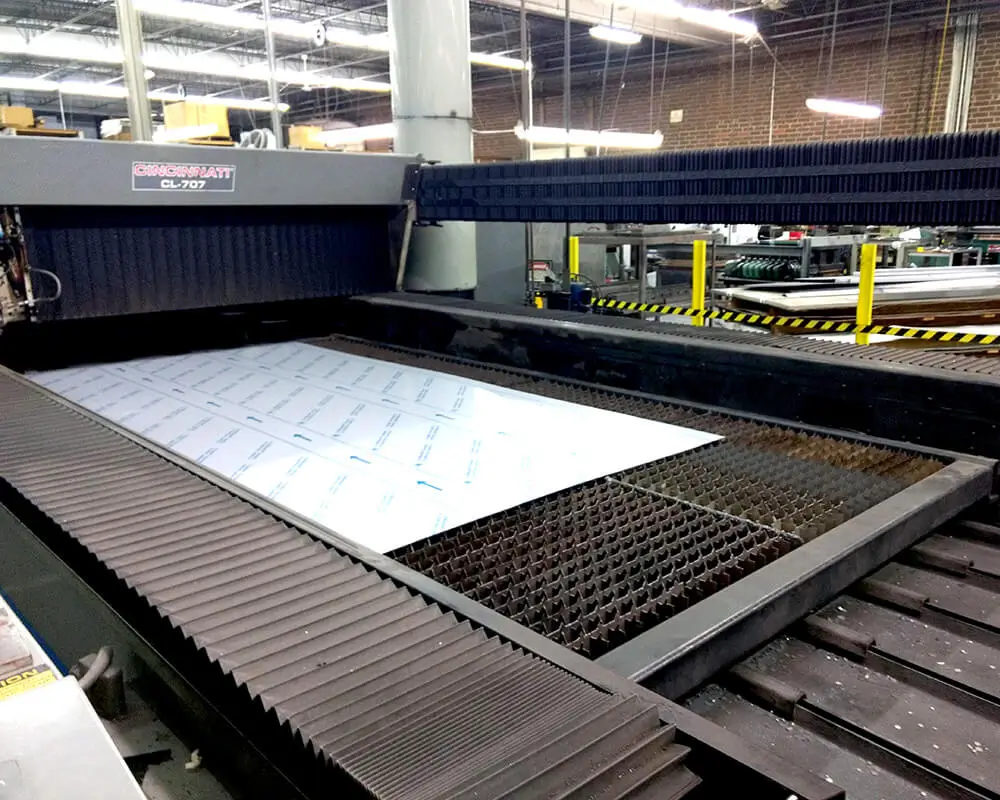

Most laser machines and laser cutting systems utilize special types of bellows for efficient functioning. The beams path and optics in these systems are extremely sensitive and need to be protected from particles, dust, and several other contaminants. Thus, axes in these systems utilize bellows that offer excellent protection to its beam path and optics. The bellows are made from materials that don’t deflect or absorb the laser beam passing through it, yet allows nitrogen or purified air to pass through it.

Most laser machines and laser cutting systems utilize special types of bellows for efficient functioning. The beams path and optics in these systems are extremely sensitive and need to be protected from particles, dust, and several other contaminants. Thus, axes in these systems utilize bellows that offer excellent protection to its beam path and optics. The bellows are made from materials that don’t deflect or absorb the laser beam passing through it, yet allows nitrogen or purified air to pass through it.

Specifications of Laser Bellows Provided by Nabell USA

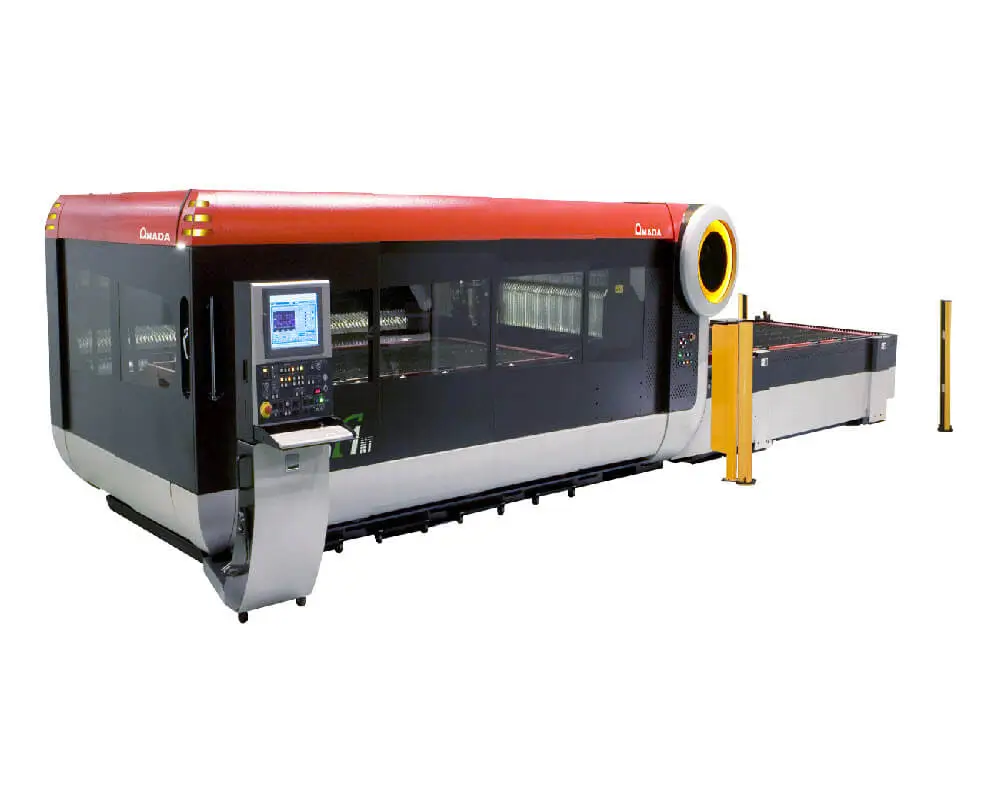

Being one of the reliable and known laser bellows manufacturers in USA, Nabell provides bellows for laser cutting and processing operations for various laser machine brands and models. Our vast industrial experience and advanced technical capabilities have helped us immensely to become one of the leading laser cutting system bellows manufacturers in the USA.

- Applied Processes: Our laser bellows are manufactured through various techniques including thermal welding, combination and perforation folding, and sewing. These bellows are perfectly shaped, which also improve their impact resistance and ensure lasting performance.

- Base Materials: Our bellows for laser cutting machines are made using durable, heat resistant, and flame-resistant materials such as aluminized Kevlar, polyurethane-coated polyester, silicone fiberglass cloth, polyurethane-coated nylon, preoxidized Kevlar, polyurethane-coated Nomex, and PVC-coated polyester.

- Shapes: A square or polygonal shape is typical, however, we can custom manufacture most any shape you prefer.

- Material Thickness: The bellows for laser cutting and processing systems can be availed in material thickness ranging from 0.2mm to 1.17mm.

- Colors: Black is the most common color preferred, however, in many cases, we can provide custom color matching, depending on the material of choice.

- Packaging: The bellows are delivered in a customer-specified packaging to ensure their safety during transportation.

- Delivery Times: We assure the shortest lead-times of four to five weeks for prototypes.

- File Types Accepted: The design files are accepted in different formats such as DWG, STEP, DXF, and Native SolidWORKS.

- Tooling Costs: In most cases, we don’t charge any tooling costs to our clients.

Certifications & Standards

Quality is the commitment that guides us at Nabell USA. Over the years, we have tried to fulfill this commitment by investing in manufacturing technologies and materials that are known to perform. The following certifications and standards are the attestation of our commitment to quality.

- ISO 9001:2015

- UL94-VTM0 test standard for wire insert bellows

Being one of the leading and trusted laser system bellows manufacturers in the US, we believe in delivering 100% customer satisfaction. Our experts work closely with customers to understand their requirements. They help them choose the right material for their laser cutting bellows. Everything right from designing to manufacturing and delivery is handled by seasoned experts. Our in-depth knowledge on laser cutting industrial requirements have helped us serve clients across the globe efficiently. If you are looking for laser bellows manufacturers in North Carolina, do contact us to know more and share your requirements. We would be happy to assist you.

Additional Information :

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Thermal Welding, Perforated Fold, Combination Fold, Sewn Shape |

| Material Thickness | 0.2mm ~ 1.17mm |

| Base Material Selection | Aluminized Kevlar, Polyurethane coated Polyester, Silicone Fiberglass cloth, Polyurethane coated Nylon, preoxydized Kevlar, Polyurethane coated Nomex and PVC Coated Polyester |

| Color | Varies depending on material choice.We can also provide most any preferred color. |

| Packaging | To customers specifications |

| Industry for Use | Laser Cutting, machining |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Costs | In most cases, we don’t charge any tooling costs to our clients |

Laser Cutting Bellows Quote Request Form

Laser Cutting Bellows Quote Request Form