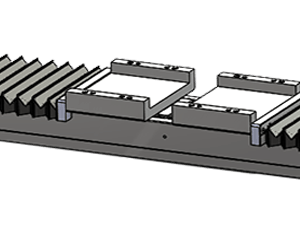

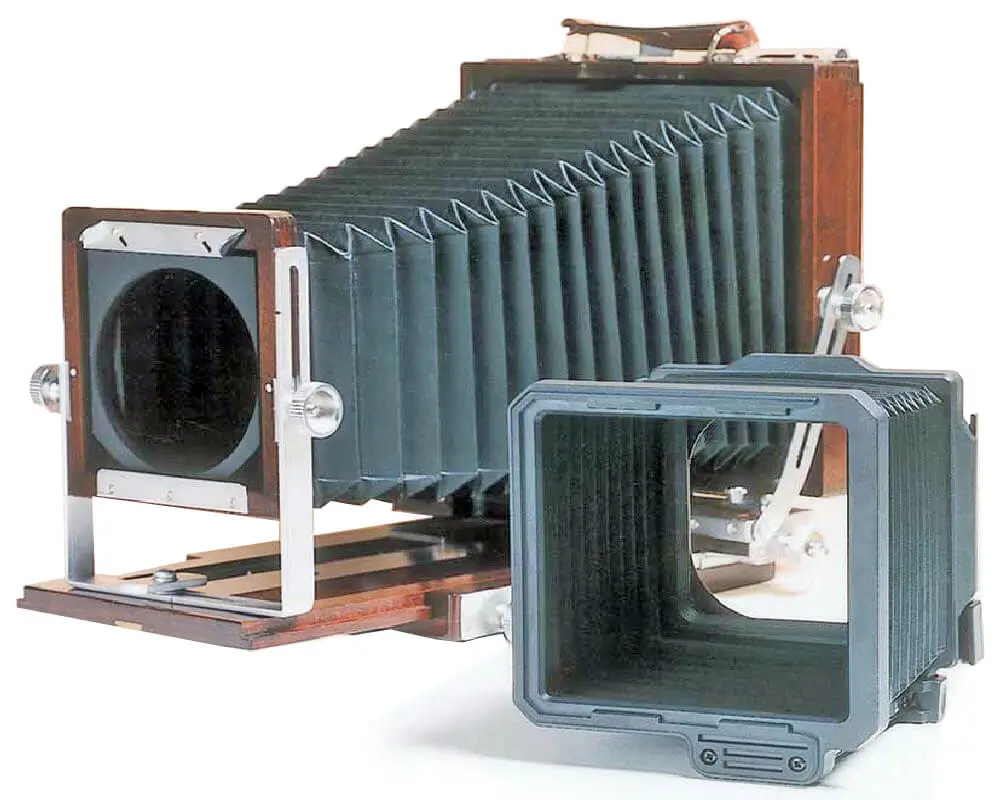

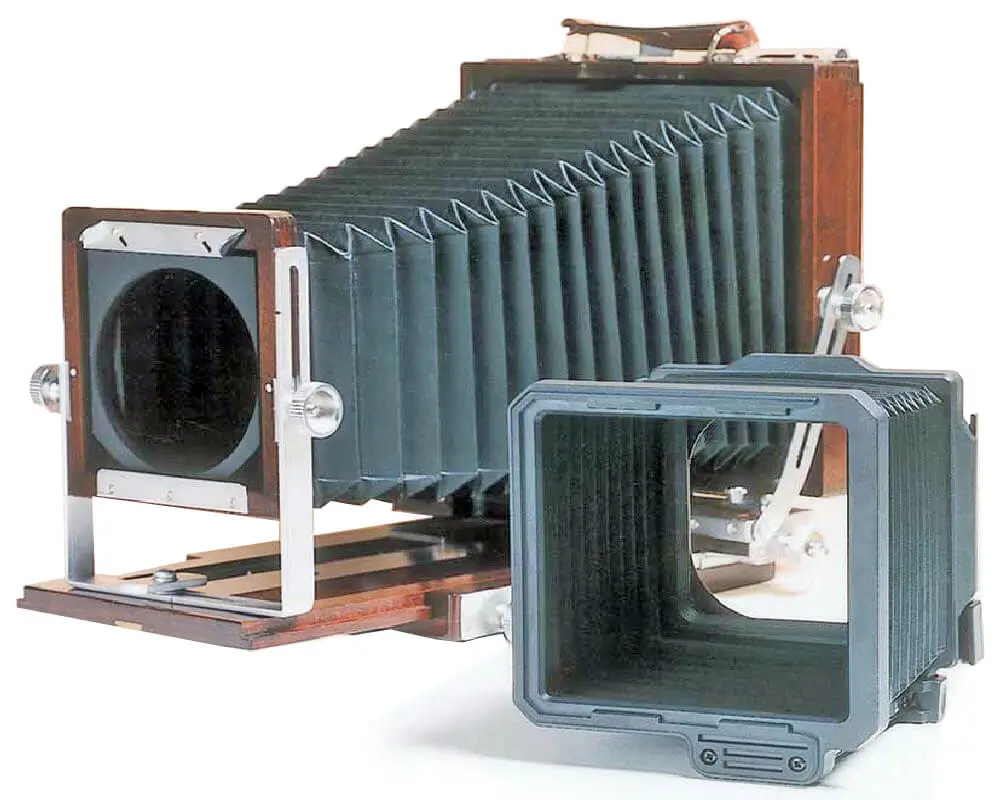

Tapered Bellows

Tapered bellows are widely used in cameras and optical applications. These are typically made of a polyurethane coated nylon, paper or leatherette materials. They are suitable for applications where a light-seal is required, but can be manufactured to protect against high temperatures and pressures, as well. At Nabell USA Corp, we make tapered bellows for various industries including Scientific, Industrial, Camera and Optical. Size is rarely an issue for our tapered bellows engineers.

Tapered bellows are widely used in cameras and optical applications. These are typically made of a polyurethane coated nylon, paper or leatherette materials. They are suitable for applications where a light-seal is required, but can be manufactured to protect against high temperatures and pressures, as well. At Nabell USA Corp, we make tapered bellows for various industries including Scientific, Industrial, Camera and Optical. Size is rarely an issue for our tapered bellows engineers.

Specifications of Tapered Bellows by Nabell

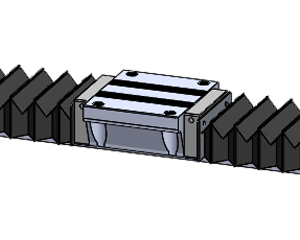

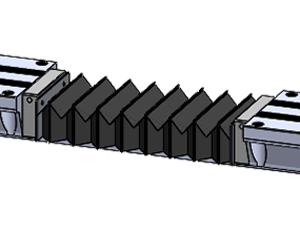

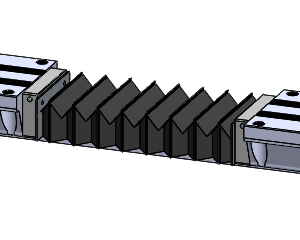

Widely established as an industry-leader with best-in-class processes and a qualified team of engineers, we are equipped to customize your bellows on par with your application requirements. Simple to install and affordably priced, our tapered bellows are made utilizing the following specifications.

- Applied Processes: Made from high-quality materials and fabrics, our tapered bellows manufactured utilizing our perforated fold, combination fold, sewing and laminating techniques. Our expertise in these processes enable us to help you design a perfect fit for your application.

- Material Thickness: The thickness of these tapered bellows varies between 0.2mm and 0.53mm.

- Base Materials: We have a diverse inventory of base materials including:

- Aluminized coated Nylon

- Polyurethane coated Polyester

- Silicone Fiberglass cloth

- Polyurethane coated Nylon

- Polyurethane coated Nomex

- Material Thickness: With a single layer or multi-layer construction including outer fabric, core material(s), and inner fabric, the above-mentioned materials for our roll screen covers have a thickness ranging from 0.2mm ~ 0.53mm.

- Color: Dependent on base material and applied process. Custom colors may be available.

- Packaging: We individually package and adhere to your specific requirements.

- Delivery Time: Our general delivery is 4-5 weeks for our roll screen bellows. We also work to accommodate rush orders, especially customers with MRO requirements.

- File Types Accepted: DWG, DXF, STEP, and Native SolidWORKS formats.

- Tooling Costs: Generally, None

Applications of Tapered Bellows

Our high-quality tapered bellows have a large application across many industries, especially where getting the right size of protective covers is a concern. They are also used in applications where dust and other environmental elements are strictly prohibited. Here are a few application areas of tapered bellows listed:

- Optics and cameras

- Electronic devices

- Equipment in healthcare

- Construction

- Aerospace

- Defense

- Transportation

Certifications and Standards

With over forty-seven years of world-class design and manufacturing experience, compliance and certification requirements have become a “norm” for us and the industries we serve. We utilize ISO 9001:2015 as our Quality Management System and meet or exceed many standards such as; REACH, RoHS, COC, FAIR CONFLICT Minerals, UL94 VTM-0 (flame-resistant test) and many other special requirements from our customers.

We are experts at designing tapered bellows as we have been rooted in the camera industry since 1972. Talk to a Nabell engineer, for a no cost consultation, to see what we can do for you, today.

Additional Information :

| Product Specification | |

|---|---|

| Capabilities Applied/Processes | Perforated Fold |

| Material Thickness | 0.2mm ~ 0.53mm |

| Base Material Selection | Polyurethane coated Nylon and others |

| Color | Varies depending on material choice |

| Packaging | To customers specifications |

| Delivery Time | Generally 4-5 weeks |

| Drawing Type Accepted | DWG, DXF, STEP, Native SolidWORKS |

| Tooling Cost | Generally none |

Tapered Bellows Quote Request Form

Tapered Bellows Quote Request Form